Heat welding equipment

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

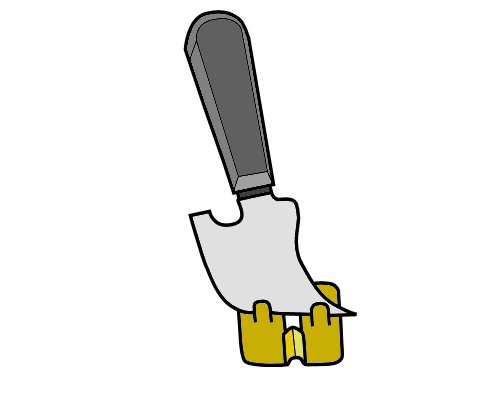

This stops dirt, moisture and other substances from getting into the joins.

The job specifications will generally set out the specific requirements for the welds, particularly in projects where hygiene is important, such as in hospitals and aged care facilities.

Audio for slide 9 (mp3 |6|KB)

Audio for slide 9 (mp3 |6|KB)

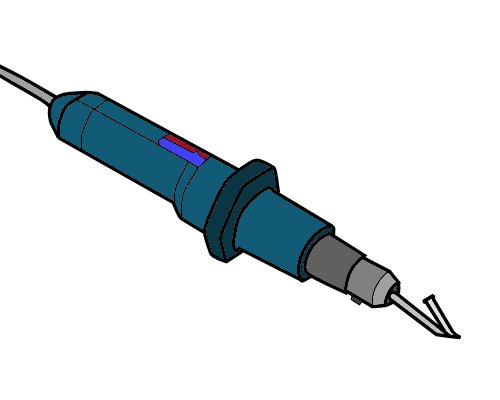

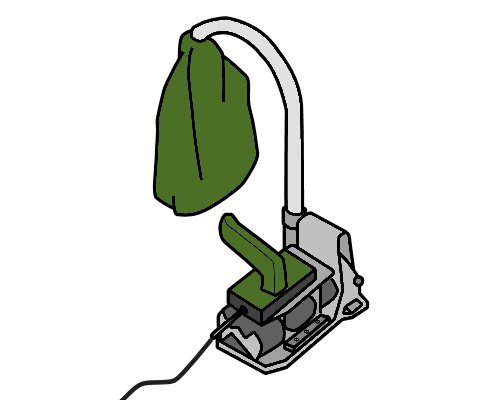

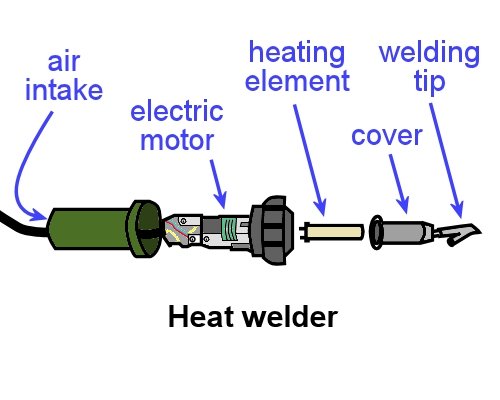

Welding gun maintenance

When it's looked after properly, a welding gun should last for many years.

The way it works is quite simple - air is sucked in at the back, heated by a heating element, and blown out through the tip.

However, if dust is allowed to build up in the air intake gauze, it can be drawn into the electric motor and cause it to overheat.

Learning activity

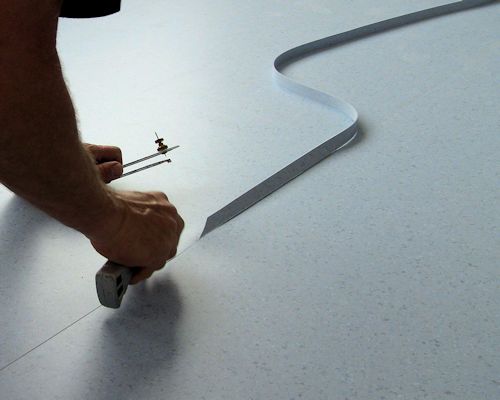

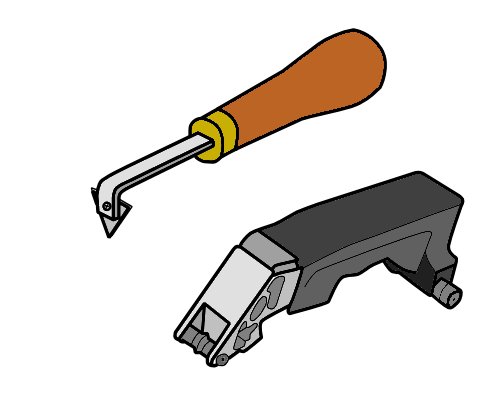

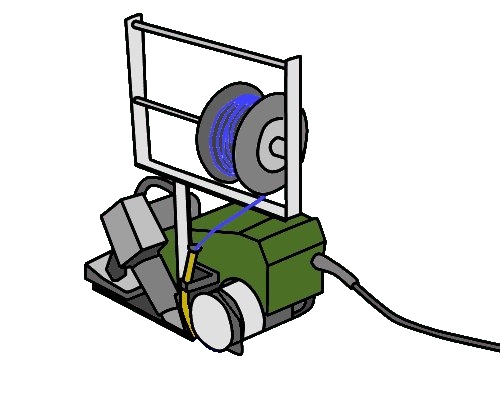

Audio 12 (mp3 |6|KB)We'll look in detail at the process of manually grooving and heat welding a seam in the next lesson. But for now, let's have a look at some of the power tools on the market designed to do these tasks.

Follow the links below to see the video clips produced by two manufacturers. Watch the videos and then answer the questions.

What blade sizes are available for the Turbo groover?

Which blade size is factory fitted?

2. Welding floor with Leister Unifloor

There is a range of nozzles available for different types of floors. What types of floors are the following three nozzles used for?

Standard

Pressed

Air knife.

Go to The welding process

Go to The welding process