Applying an adhesive

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

We covered the process of applying an adhesive in the following lesson.

Full spread installation (Lay flat vinyl)

Below is a summary of the procedure.

If you need to revise any of the details, you should go back to that lesson and read the material again.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

Notched trowels

Most adhesives are designed to be spread with a notched trowel.

The purpose of the notches is to control the amount of adhesive that's spread on the substrate.

Manufacturers sometimes specify different trowel notchings for particular flooring and adhesive products.

It's important to follow these specifications, because if you don't, you'll end up applying either too much or too little adhesive.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

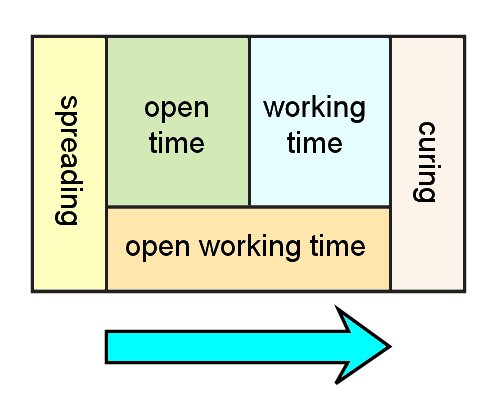

Open time

Once an adhesive has been spread, you need to wait until the open time has elapsed before placing the floor covering in position.

This is also called the tack up time, because the ridges in the adhesive start to 'skin over'.

If you place flooring onto the adhesive too soon, it traps the gasses being given off and can cause bubbles under the surface.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

Working time

When the adhesive is ready for the flooring to be placed on top, the working time begins.

This is the time you have available to lay the material and complete all cutting and fitting.

If you place flooring onto the adhesive after the working time has passed, the flooring won't bond properly.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

Variations in open and working time

The open time and working time of an adhesive will vary depending on the temperature, humidity and porosity of the surface.

High temperatures, low humidity and porous surfaces will all reduce the times.

For very porous surfaces, such as wood-based underlays, manufacturers generally specify that a primer be applied first with a brush.

This helps to avoid the problem of late placement, where the adhesive has already set and will no longer bond to the flooring covering.

Learning activity

Audio 8 (mp3 |6|KB)Go back to the Armstrong Floors 'Vinyl sheet installation video - Part 2' at:

Armstrong vinyl installation videos

This time, go to the section called 'Adhesive', which starts at 5 min 10 seconds into the clip.

Watch this section and then answer the following questions.

Acrylic sheet vinyl adhesives contain two types of resin in the compound - a 'tackifier resin' and a 'primary resin'.

- What is the purpose of the tackifier resin?

- What is the purpose of the primary resin?

Go to Problems with adhesives

Go to Problems with adhesives