Cold welding

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

Cold welding is also called chemical welding, because it uses a solvent to fuse the two sides of a seam together.

The process is applied widely to carpets and PVC products in all sorts of applications - but in resilient floors it's generally only used with cushioned vinyl that isn't suitable for heat welding.

The process is applied widely to carpets and PVC products in all sorts of applications - but in resilient floors it's generally only used with cushioned vinyl that isn't suitable for heat welding.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

You should always wait until the following day after installation before cold welding the seams.

This allows the adhesive to set and gives the moisture from the adhesive time to evaporate.

Some manufacturers recommend a full 24 hours before cold welding.

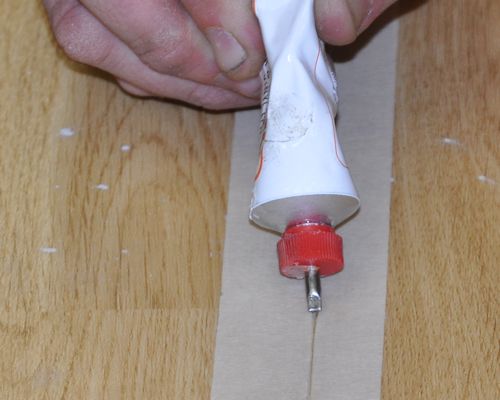

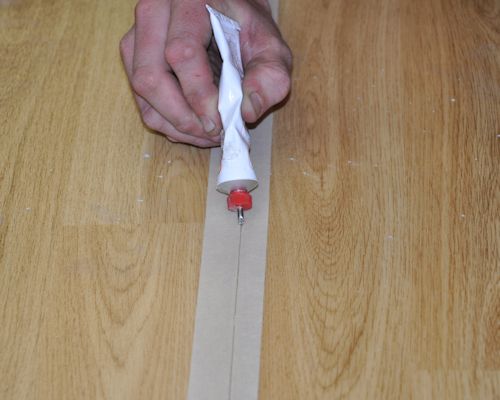

Set out below is the general procedure for seam sealing with a PVC cold welding liquid.

Typically, this product comes in a tube and is applied through a steel needle attached to the tube's nozzle.

However, there are variations on this technique, so you should always follow the specific instructions provided by the manufacturer.

This allows the adhesive to set and gives the moisture from the adhesive time to evaporate.

Some manufacturers recommend a full 24 hours before cold welding.

Set out below is the general procedure for seam sealing with a PVC cold welding liquid.

Typically, this product comes in a tube and is applied through a steel needle attached to the tube's nozzle.

However, there are variations on this technique, so you should always follow the specific instructions provided by the manufacturer.

Learning activity

Audio 5 (mp3 |6|KB)The link below will take you to a video clip produced by Johnsonite Flooring on how to do a cold weld.

Watch the video and then answer the following questions:

- What tool does the installer use to press the masking tape down firmly onto the flooring?

- What angle does he hold the tube at while he is applying the cold weld liquid.

Go to Finishing the job

Go to Finishing the job