Types of adhesives

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

There is no single adhesive that's suitable for all types of resilient floor coverings.

The best adhesive for any particular job will depend on a range of factors, including what type of material is being laid, what the substrate is made from and how much wear and tear the floor will be subjected to.

The best adhesive for any particular job will depend on a range of factors, including what type of material is being laid, what the substrate is made from and how much wear and tear the floor will be subjected to.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

The selection of the most appropriate adhesive is generally made by the floor covering manufacturer and specified in the installation instructions.

However, there are times when the client may have unusual site conditions or requirements, and an alternative adhesive needs to be used.

In these cases, you should always check with the flooring manufacturer before going ahead - otherwise you may find that you've voided the warranty conditions.

Below are the main categories of adhesives used with sheet vinyl installations.

Note that with the continuing development of new chemical compounds and combinations of compounds, some products may fall into more than one category.

However, there are times when the client may have unusual site conditions or requirements, and an alternative adhesive needs to be used.

In these cases, you should always check with the flooring manufacturer before going ahead - otherwise you may find that you've voided the warranty conditions.

Below are the main categories of adhesives used with sheet vinyl installations.

Note that with the continuing development of new chemical compounds and combinations of compounds, some products may fall into more than one category.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

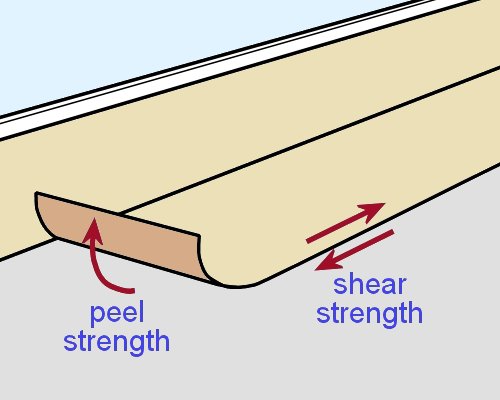

This gives them a high peel strength, meaning that the floor covering does not peel away easily from the substrate.

But their shear strength is not as good, which means that they are less resistant to forces that tend to slide one layer against another.

This can be a problem in areas where there might be movement in the subfloor, such as on steel floors around gantry cranes.

But their shear strength is not as good, which means that they are less resistant to forces that tend to slide one layer against another.

This can be a problem in areas where there might be movement in the subfloor, such as on steel floors around gantry cranes.

Audio for slide 9 (mp3 |6|KB)

Audio for slide 9 (mp3 |6|KB)

Although their bond strength is excellent, they are generally water soluble, which makes them unsuitable for use in wet areas.

Acrylics generally have a longer open time than other adhesives and are non-toxic and non-flammable.

They are also highly resistant to plasticiser migration (see the next lesson for details on this problem).

Acrylics generally have a longer open time than other adhesives and are non-toxic and non-flammable.

They are also highly resistant to plasticiser migration (see the next lesson for details on this problem).

Audio for slide 12 (mp3 |6|KB)

Audio for slide 12 (mp3 |6|KB)

Looking to the future

In recent years there has been an enormous amount of research into new formulations for adhesives.

The challenge has been to find products that are less damaging to the environment and the health of installers who use them.

The main problem for scientists has been that many of these more 'environmentally friendly' water based products are less effective than the adhesives they are designed to replace.

Audio for slide 13 (mp3 |6|KB)

Audio for slide 13 (mp3 |6|KB)

Learning activity

Audio 14 (mp3 |6|KB)Choose two sheet vinyl products that are designed for different purposes and get a copy of the manufacturer's installation instructions.

Check that the two products specify different types of adhesive.

For each product, answer the following questions:

- What is the brand name and who is the manufacturer of the flooring?

- What adhesive brand name is recommended for laying the flooring?

- What type of adhesive is it - that is, what category does it fall into?

Go to Planning and preparation

Go to Planning and preparation