Handling and conditioning

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

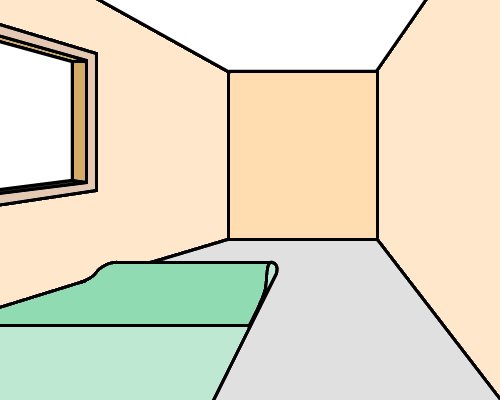

This puts the material under tension, which is only released when the material is unrolled again.

As the material returns to normal, it will shrink slightly in length.

The best way to avoid problems with shrinkage is to re-roll a cut length back on itself and wait for about 15 minutes.

Then you can unroll it again and start fitting it in position.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

Then scribe the second end, spread the remaining adhesive and stick that end down.

Note that the whole sheet must be stuck down before the adhesive sets. If the first part starts to set before you lay down the last section, any overspread in adhesive might result in bubbles where the two parts meet.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

Conditioning

Before you begin an installation, you need to let the floor covering condition to the surrounding temperature and humidity in the room.

This process is also called acclimatisation.

AS 1884 says that floor coverings should be conditioned for at least 24 hours, or until the product has achieved an 'ambient room temperature' range of between 15° and 28° C.

For more information on the conditioning process, including the procedures you should follow in buildings with air conditioners or heated floors, go to the lesson shown below.

Conditioning (Preparing floor coverings)

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

Batch lots

Floor coverings are manufactured in batch lots, also called dye lots.

Each roll of material has a batch number on the packaging to indicate which batch of colour dyes was used in that particular manufacturing run. It will also have a roll number.

Where possible, you should try to use flooring with the same batch number and sequential roll numbers when they are being placed side by side.

This will help to provide the best match of colours and avoid any inconsistency in shade or intensity.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

There will be times, however, when you won't have access to a dolly on-site and you'll have to make do with your own manual handling skills.

In these cases, you should roll out the material on the floor with the face side down, and then turn it over.

The learning activity below will give you some hints on how to turn over a long sheet without damaging the material or straining yourself.

Learning activity

Audio 7 (mp3 |6|KB)Go to the web link below to see a video clip produced by Altro Flooring:

Altro handy hint - turning over a length of Safety Flooring without any lifting

Watch the clip and answer the following questions:

- When the demonstrator doubles the flooring over, he rolls the top layer several times before lifting the bottom layer up over the top. How many times does he suggest you should roll the top layer before you lift the bottom layer up?

- Underneath the video clip there are some viewers' comments. One entry asks: 'Does it work for linoleum?'. What advice does Altro Flooring give, and why is it necessary to use a slightly different technique for linoleum?

Go to

Go to