On-site issues

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

It's sometimes the case that there is no single big problem responsible for high moisture or pH levels.

Instead, there may have been several contributory factors that all played a role.

Here's an example of what can happen on a jobsite where the builder or client is pushing the installer to get the job done quickly:

- the installer starts work before the concrete has reached 70% RH in all test areas (using an insulated hood)

- the levelling compound is mixed with a bit too much water

- the flooring adhesive is applied before the levelling compound has fully cured.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

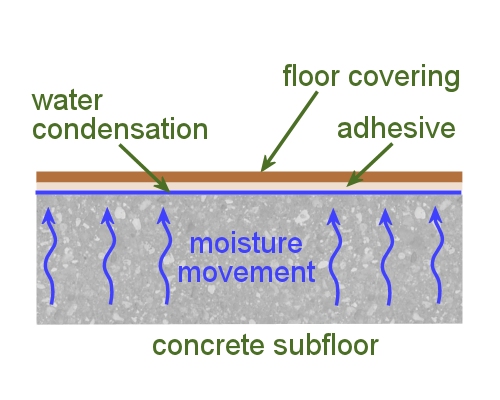

However, the moisture can no longer escape through the surface because the floor covering is restricting its free evaporation.

So it condenses into liquid water and begins to degrade the adhesive and flooring materials.

Sheet vinyl and solid timber flooring tend to fare the worst when there's a difference in humidity levels between the subfloor and the air inside the room.

But all floor coverings can be affected if the humidity differences are large enough or remain a problem for long enough.

So it condenses into liquid water and begins to degrade the adhesive and flooring materials.

Sheet vinyl and solid timber flooring tend to fare the worst when there's a difference in humidity levels between the subfloor and the air inside the room.

But all floor coverings can be affected if the humidity differences are large enough or remain a problem for long enough.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

Air conditioners

Australian Standard 1884-2012 says that when air conditioning units are being installed in a new building, no underlay or floor covering should be laid on the subfloor until the unit has been operating at the expected temperature and humidity levels for at least seven days.

The unit should be kept running continuously during the laying process and for a further 48 hours.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

In the case of solid timber flooring, manufacturers often state in their warranty conditions that the boards must be allowed to 'acclimatise' to the room humidity levels for at least two weeks prior to laying.

Again, when an air conditioner has been installed, it must be running continuously during the acclimatisation period.

Again, when an air conditioner has been installed, it must be running continuously during the acclimatisation period.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

Note that these requirements assume that the subfloor humidity has already dropped to an acceptable level, or the surface has been properly coated with a moisture barrier.

If you're still waiting for the concrete to dry or there are other problems causing high moisture levels, you'll need to deal with those issues first before you start acclimatising the flooring materials.

If you're still waiting for the concrete to dry or there are other problems causing high moisture levels, you'll need to deal with those issues first before you start acclimatising the flooring materials.

Go to

Go to