Moisture and pH problems

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

But before you can decide on the best course of action to deal with moisture and pH problems, you need to know where the water is coming from.

The most obvious source of moisture is the excess water that's put into the concrete mix to make it flow easily into the formwork and finish with a trowel.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

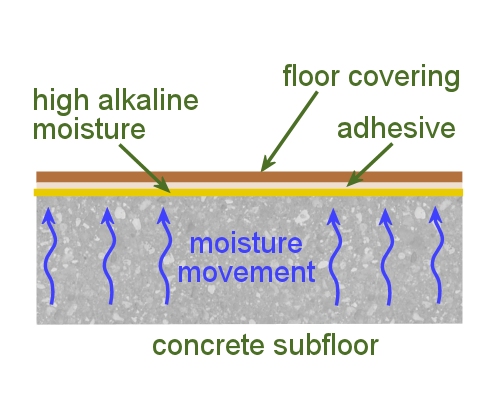

When this happens, the moisture can travel through the cracks and pores in the concrete and make its way up to the underside of the floor covering.

Because it happens out of sight, the moisture can cause a lot of damage to the flooring adhesive and floor covering before it becomes noticeable on the surface.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

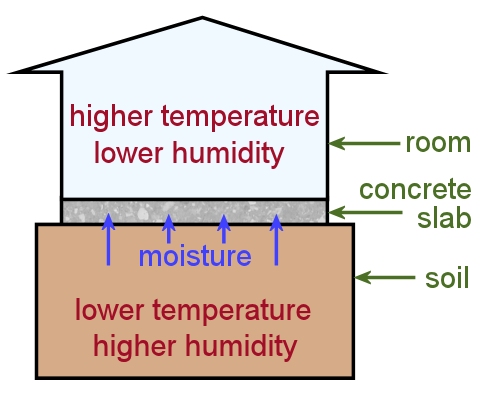

So it tends to move from areas of low temperature and high humidity to areas of high temperature and low humidity until that balance is restored.

Below are the main factors that affect the movement of moisture in concrete. Once we've looked at these mechanisms, we'll discuss the effect they can have on pH levels.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

Construction moisture

'Green' (or fresh) concrete always starts off with a very high moisture content.

In reality, only about one third of the water in wet concrete is needed for the hydration process. The remainder is there to make it more workable.

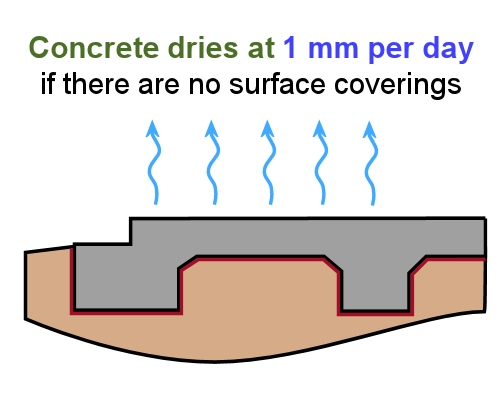

Before the concrete can reach EMC (equilibrium moisture content) with the surrounding atmosphere inside the building, the excess water has to evaporate from the surface.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

This means that a 100 mm thick slab will take about 100 days to dry.

But the rule only applies if there is no curing compound on the surface or any other covering that might slow down the drying process - so it can often take much longer.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

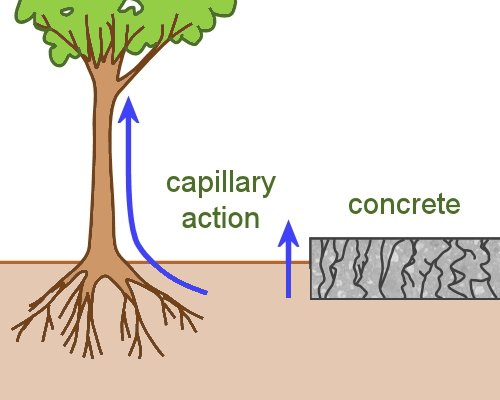

Capillary action

Capillaries are tiny spaces that allow a liquid to flow through.

Capillary action occurs as a result of the 'attractive force' between the molecules of a liquid and the 'adhesive force' of the very small spaces.

This allows the liquid to flow against the pull of gravity.

You can see it happen when blotting paper absorbs ink. It's also the force that allows plants to draw moisture up from the roots to the leaves, and a kerosene lamp to draw fuel through the wick.

Audio for slide 7 (mp3 |6|KB)

Audio for slide 7 (mp3 |6|KB)

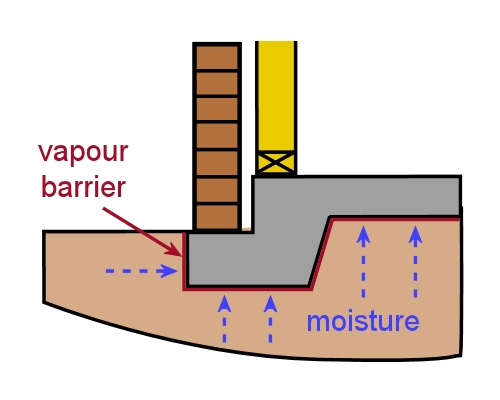

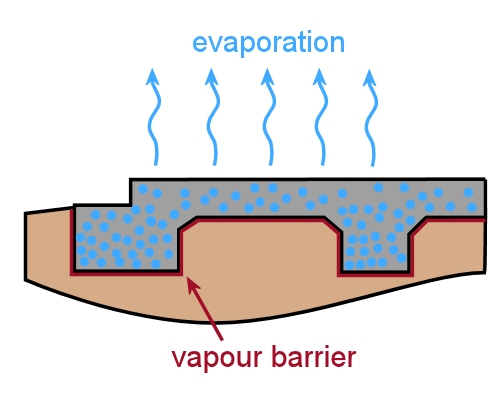

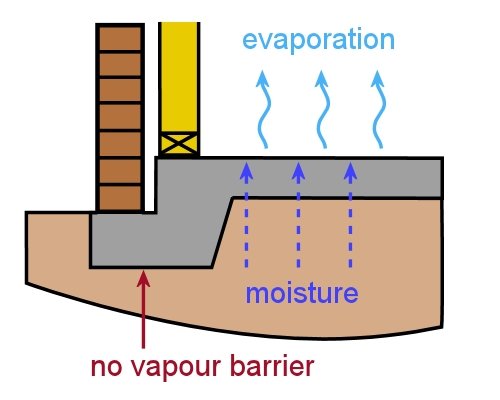

If there is no vapour barrier underneath the slab and the soil is wetter than the concrete, moisture will be drawn up through the tiny cavities and evaporate from the surface.

This is a common problem with slabs that are more than 50 years old, because it was not standard building practice in those days to install vapour barriers.

Even if you cover the concrete surface with a floor covering, the moisture will still rise, but because it can't evaporate into the air it will accumulate under the floor covering.

Audio for slide 8 (mp3 |6|KB)

Audio for slide 8 (mp3 |6|KB)

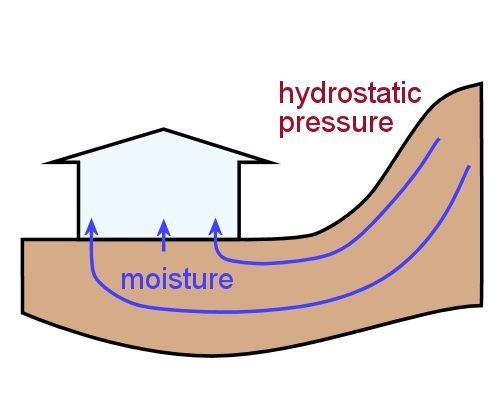

Hydrostatic pressure

'Hydro' means water and 'static' means stationary.

Hydrostatic pressure is the pressure exerted by still water due to the force of gravity, as opposed to flowing water.

It becomes a problem for on-grade or below-grade concrete slabs when the surrounding land is higher on any side.

If there is no membrane separating the slab from the soil, the build-up of hydrostatic pressure can eventually force the moisture up through the slab.

Audio for slide 10 (mp3 |6|KB)

Audio for slide 10 (mp3 |6|KB)

Moisture can also enter through the sides of a slab if the membrane has not been turned up all the way around.

Audio for slide 11 (mp3 |6|KB)

Audio for slide 11 (mp3 |6|KB)

pH levels

Wet concrete has a very high pH level, or alkalinity.

You can often see the whitish deposits of alkaline salts on the surface of drying concrete.

When the pH level is above 10, the alkaline salts can react chemically with the flooring adhesives and gradually cause the bond to fail.

Alkaline salts will also react with the PVC in certain floor coverings and make them go brittle. It can also be responsible for softening rubber-backed coverings and destroying carpet dyes.

Audio for slide 12 (mp3 |6|KB)

Audio for slide 12 (mp3 |6|KB)

Remember, though, that a freshly poured slab will naturally have high pH levels due to the chemical reaction taking place. So you only need to deal with this problem as a separate issue if the moisture has already been brought under control and the pH is still high.

Learning activity

Audio 13 (mp3 |6|KB)We've mentioned the rule of thumb that concrete dries at a rate of about 1 mm per day.

But there are lots of reasons why concrete could take much longer to dry down to a moisture content that's in equilibrium with the surrounding atmosphere.

One of these reasons is the presence of a curing compound on the surface.

How many other reasons can you think of? Make up a list and share it with other learners in your group or with your trainer.

Go to On-site issues

Go to On-site issues