Selecting the tooling

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

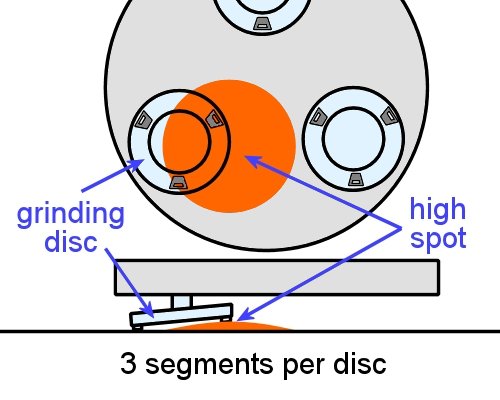

Number of segments on a disc

You may have noticed that a tripod never rocks backwards and forwards on a floor, even if the surface is uneven. This is because there are only three legs.

In the same way, three diamond segments, or 'shoes', on a grinding disc will tend to follow the surface of the floor.

This makes them good at removing old adhesives and other contaminants, because they are less likely to miss low spots and hollows in the floor.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

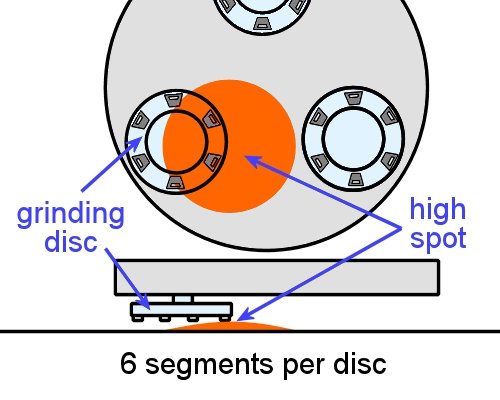

To remove undulations (or 'waves') in the floor, you need to use four or more segments.

Many machines use six segments per disc for grinding down high areas to achieve a flat surface.

This set-up also runs more smoothly and gives a finer cut, because there is less distance between the segments.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

Grit size

The lower the grit size, the coarser the diamonds will be.

So a higher grit size will give you a smoother finish, but it won't be as effective in removing heavy contaminants from the surface.

To smooth rain damaged or rough concrete, it's best to start with a grit size of around 20 to 40.

To remove contaminants, such as glues, epoxies or levelling compound, a lower grit size is better, say 20 or less.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

Bond

As we discussed in Section 1, the softer the bond, the faster it will wear and therefore the faster it will cut.

In general, use a soft bond for hard concrete and a hard bond for soft concrete.

But remember, the surface characteristics of the concrete will be just as important as its hardness when you're deciding which bond to use.

Audio for slide 7 (mp3 |6|KB)

Audio for slide 7 (mp3 |6|KB)

If you're unsure about the concrete's hardness, start with a harder bond and see how it goes.

You can always change to a softer bond if your first choice is not doing the job, and it will save you the expense of wearing out the diamonds in a segment that was too soft.

Audio for slide 8 (mp3 |6|KB)

Audio for slide 8 (mp3 |6|KB)

Diamond selection table

Some manufacturers include a diamond selection table in their operator's manual, to help you choose the right tooling for a job.

These are a good guide, but you always need to match the tooling to the actual conditions you're faced with, and modify it according to the results you're achieving.

The link below will take you to an excerpt from the Husqvarna operator's manual for their PG 680 and PG 820 planetary grinders.

Diamond selection table for PG 680 and PG 820

Learning activity

Audio 9 (mp3 |6|KB)The diamond selection table linked above provides recommendations for a wide range of job types, including concrete polishing. For the purposes of our learning unit, we're only interested in the grinding applications.

Use the table to answer the following questions:

- What is the suggested tooling and set-up for flattening undulations in medium concrete?

- What is the suggested tooling and set-up for removing vinyl or carpet glue in medium concrete?

Have a think about why these recommendations are different. Can you explain the reasons for the different choices in grit size and set-up (that is, full or half set of diamonds)?

Go to Operating procedures

Go to Operating procedures