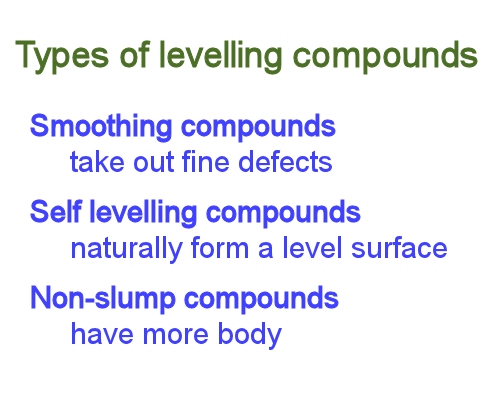

Types of levelling compounds

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

Smoothing compounds are thinly skimmed on the concrete surface as a top coat to take out fine defects in localised areas.

Self levelling compounds are used to smooth and level an entire floor area. They are poured onto the floor and naturally form a level surface once they've been spread evenly.

Non-slump compounds have more body, so they tend to stand up higher when placed on the floor. They are used for smoothing, creating 'falls' towards a floor waste, creating ramps up to a higher floor level, filling uneven areas of the floor, and repairing holes, cracks and defects.

Self levelling compounds are used to smooth and level an entire floor area. They are poured onto the floor and naturally form a level surface once they've been spread evenly.

Non-slump compounds have more body, so they tend to stand up higher when placed on the floor. They are used for smoothing, creating 'falls' towards a floor waste, creating ramps up to a higher floor level, filling uneven areas of the floor, and repairing holes, cracks and defects.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

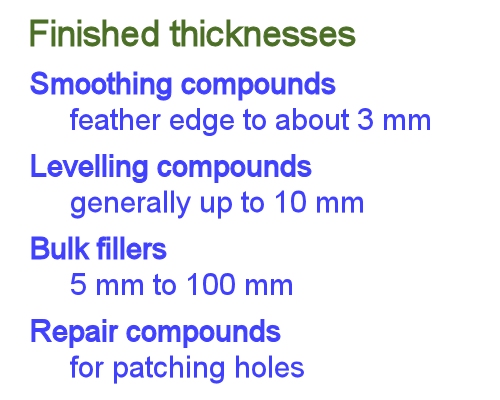

Finished thickness

The amount of body or slump in the compounds can also be categorised in terms of the product's finished thickness on the floor. For example:

- Smoothing compounds are applied in one pass, in thicknesses ranging from a feather edge up to about 3 mm.

- Levelling compounds are applied in one pass but can often accommodate thicknesses of 10 mm or more.

- Bulk fillers are applied in one pass, typically in a layer that's at least 5 mm thick and sometimes up to 100 mm.

- Repair compounds are used for patching holes and compensating for large height differences, and can be built up in separate layers.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

Binding agents

Different binding agents are used to give the levelling compounds particular characteristics, such as speed of curing and suitability for certain substrates and adhesives.

Mineral compounds can be either cement based or calcium sulphate based.

They are mixed with cold water to form a paste and then spread over the floor.

For thicker layers, sand can be added as a filler.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

Dispersion compounds contain water-based synthetic resins, mineral fillers and other components.

Most products are ready to use from the container, and don't need to be mixed with water.

Reaction resin compounds are used for patching and grouting.

Most formulations are based on polyurethane or epoxy resin and are supplied as two-part systems which are mixed together immediately before use.

Most products are ready to use from the container, and don't need to be mixed with water.

Reaction resin compounds are used for patching and grouting.

Most formulations are based on polyurethane or epoxy resin and are supplied as two-part systems which are mixed together immediately before use.

Go to Applying primers

Go to Applying primers