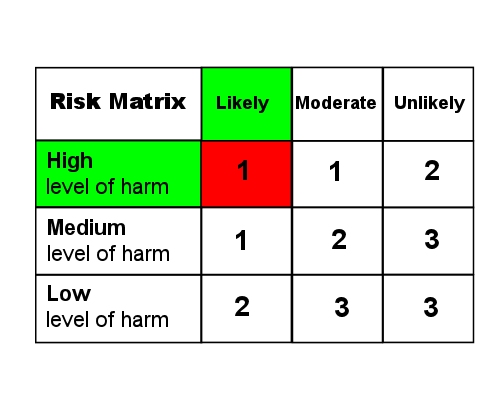

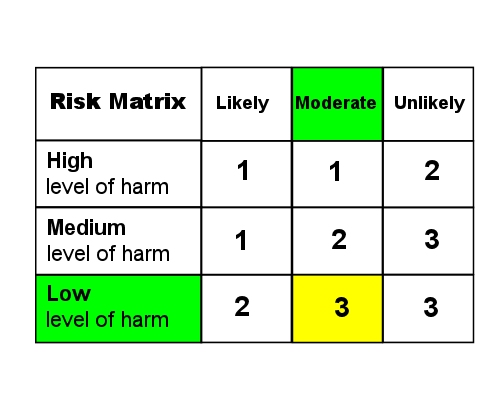

Assessing risks

| Risk Matrix | Likely Could happen frequently | Moderate Could happen occasionally | Unlikely May occur, but only in exceptional circumstances |

|---|---|---|---|

| High level of harm Death, permanent disability, major structural failure or damage | 1 | 1 | 2 |

| Medium level of harm Temporary disability, minor structural failure or damage | 1 | 2 | 3 |

| Low level of harm First aid required | 2 | 3 | 3 |

(Adapted from the 'OHSE Risk Matrix' developed by WorkCover for its 'SubbyPack')

Go to Controlling risks

Go to Controlling risks