Drill operation

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

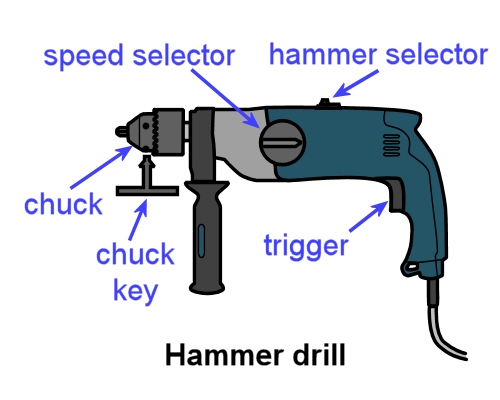

However, if you're drilling holes in concrete or brick, you'll need to use a hammer drill with a masonry drill bit.

Hammer drills have a 'hammer' and a 'normal' setting.

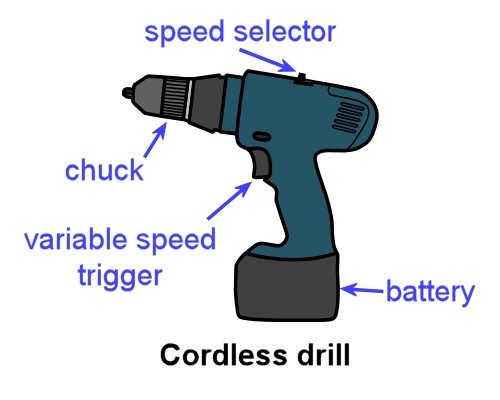

It is possible to buy good quality cordless hammer drills, but in general they're not as powerful as an equivalent-sized 240 volt drill.

Click on the link below to see a basic SOP for a drill.

Learning activity

Audio 3 (mp3 |6|KB)Different types of drill bits are used for drilling different materials and hole sizes.

See if you can name the type of bit used to drill the following holes.

- 6 mm hole in a piece of timber

- 32 mm hole in a sheet of plywood

- 12 mm hole in a concrete slab.

If you're not familiar with the drill bits used for these purposes, ask your trainer or supervisor to show you examples. You can also look them up on the web.

Go to Jigsaw operation

Go to Jigsaw operation