Electrostatic discharge can occur just about anywhere. But in some work situations it is a problem that's serious enough to require a particular type of floor covering.

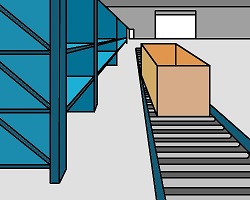

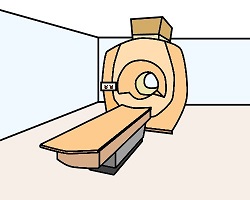

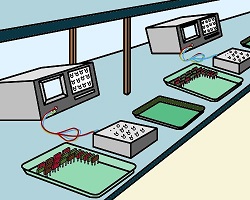

Below are three different work environments. Each one requires an appropriate antistatic or ESD floor covering, depending on the amount of ESD control required.

See if you can match up the most suitable type of flooring for each situation, as well as the typical electrical resistance in the floor surface.

Note that one of these floor coverings is not measured in terms of surface resistance, because its purpose is only to reduce the build-up of static electricity, not to control the discharge. This one is referred to as 'Not strictly ESD'.

Look at the situation then using the dropdown boxes select the correct flooring type and surface resistance.