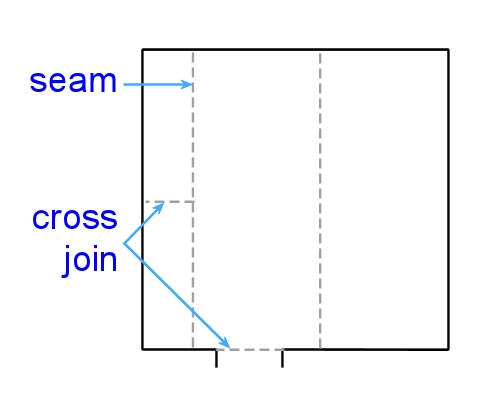

Seams and joins

Audio for slide 8 (mp3 |6|KB)

Audio for slide 8 (mp3 |6|KB)

Using a utility knife

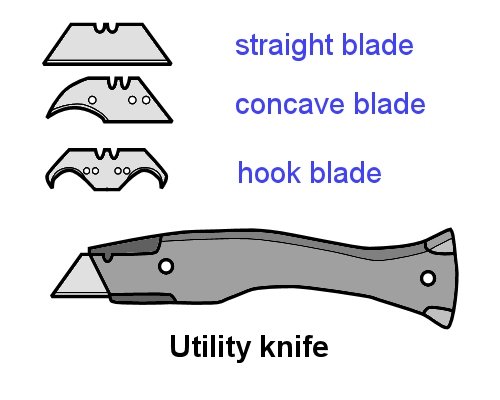

The most common tool used for cutting is the utility knife.

Because it's relatively thin, lay flat vinyl can be cut in a single pass with a straight, concave or hook blade.

You can use the straight blade for general cutting.

The concave blade is better for more precise cutting, such as around door frames.

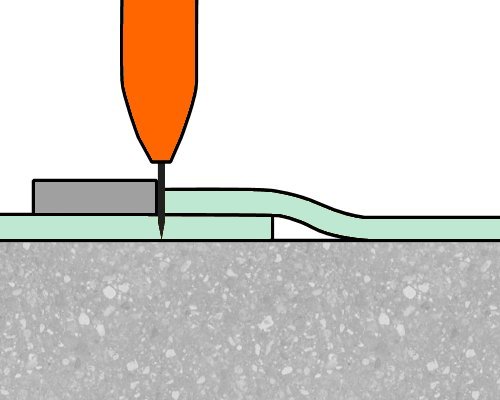

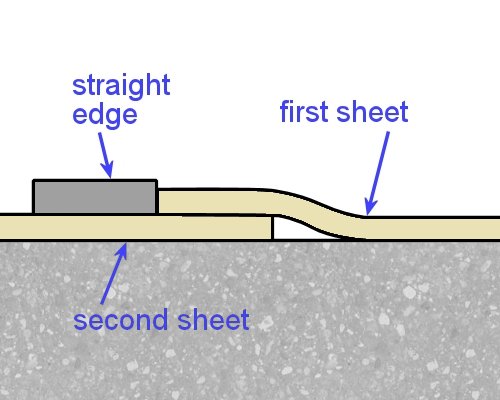

The hook blade has a flat heel, which stops the cutting edge from coming into contact with the surface underneath. This allows you to cut on a concrete floor or on top of another resilient sheet.

Audio for slide 9 (mp3 |6|KB)

Audio for slide 9 (mp3 |6|KB)

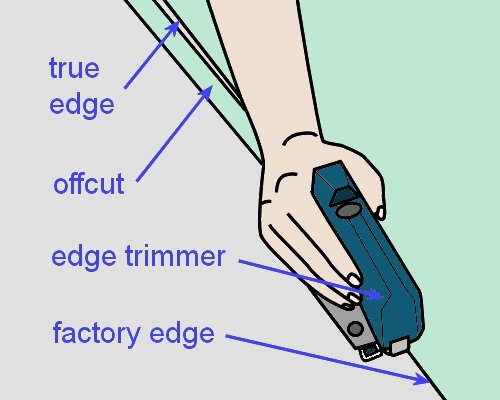

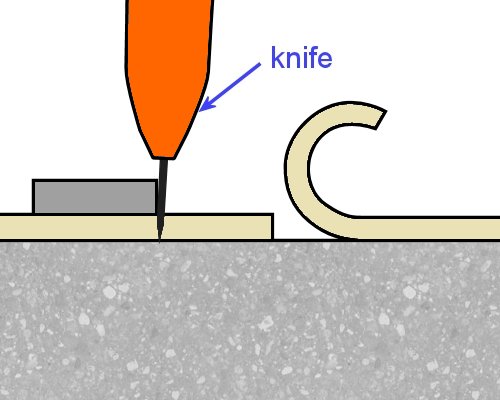

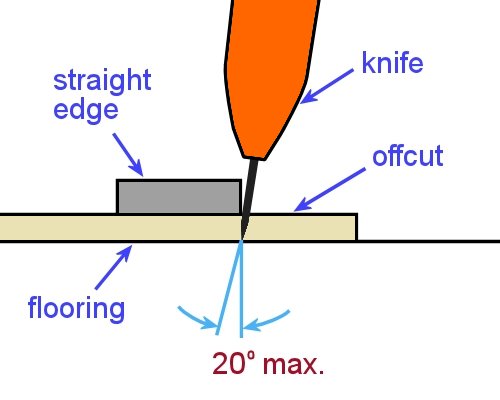

Most people tend to undercut the material slightly when the offcut is on the outside of their cutting hand.

This is not a bad thing, because it gives you a sharp edge that butts cleanly against the next sheet or the wall.

But be careful that you don't undercut too much.

If the undercut is more than about 20 degrees from the vertical, the edge might become too weak and break or fold over when it's butted up.

This is not a bad thing, because it gives you a sharp edge that butts cleanly against the next sheet or the wall.

But be careful that you don't undercut too much.

If the undercut is more than about 20 degrees from the vertical, the edge might become too weak and break or fold over when it's butted up.

Go to Freehand cutting

Go to Freehand cutting