Audio for slide 2 (mp3)

Audio for slide 2 (mp3)

Resilient floor products are the most versatile floor coverings on the market. Apart from being easy to maintain and keep clean, they can be used in situations ranging from special-purpose buildings to domestic kitchens.

Audio for slide 3 (mp3)

Audio for slide 3 (mp3)

A few years ago some of these products had an image problem, especially in offices and domestic applications. That is, they were often considered functional but not very 'classy'. But this perception is rapidly changing as the variety of products and designs continues to increase.

Audio for slide 4 (mp3)

Audio for slide 4 (mp3)

In this unit, we'll examine a very popular type of resilient floor covering - lay flat vinyl. We'll look at the structure of the product, methods of installation and some of the general issues you need to deal with when you're working on-site and preparing for installation.

Audio for slide 8 (mp3)

Audio for slide 8 (mp3)

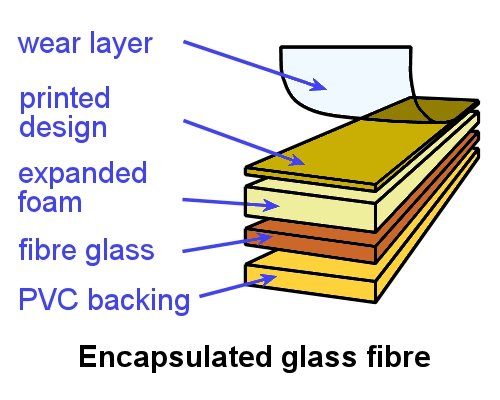

Lay flat vinyl gets its name from the fact that it has a very stable structure, and doesn't curl up at the edges like other resilient sheet products. Its stability comes from the layer of fibreglass that helps to balance the other layers. In this section, we'll look at the structure of lay flat vinyl to see how the different layers are arranged. We'll also discuss the adhesives used to stick it down and the tools and equipment required to carry out the installation.

Audio for slide 10 (mp3)

Audio for slide 10 (mp3)

Lay flat vinyl is a form of heterogeneous vinyl. This means it is made up of several layers. The term 'heterogeneous' is used to distinguish multi-layered products from 'homogeneous' vinyl, which is uniform throughout. We deal with homogeneous products in the unit: Commercial vinyl.

Audio for slide 11 (mp3)

Audio for slide 11 (mp3)

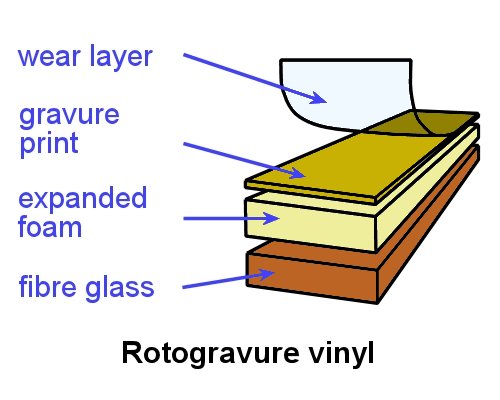

The most common structure for lay flat vinyl is encapsulated glass fibre, where the fibreglass layer is surrounded by PVC (polyvinyl chloride). In the middle is a layer of expanded foam, which improves the floor covering's softness underfoot. This product is also referred to as 'cushioned vinyl'.

Audio for slide 12 (mp3)

Audio for slide 12 (mp3)

An alternative structure is rotogravure vinyl, which is made using a rotating 'gravure' cylinder to print the pattern. After the print dyes set, a clear wear layer is put on the surface. The life expectancy of the patterned finish depends on the durability of the wear layer.

Audio for slide 13 (mp3)

Audio for slide 13 (mp3)

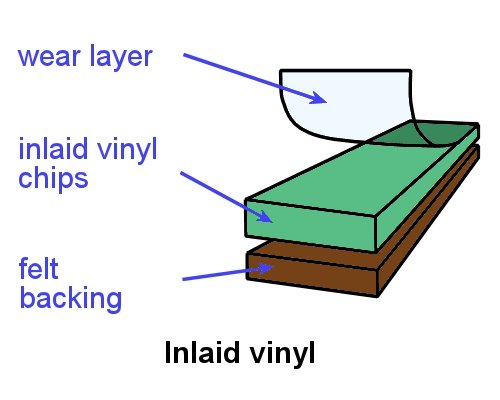

Less common is inlaid vinyl, although it is still a popular structure for certain lines of resilient tiles. Inlaid vinyl is made from solid vinyl particles fused to a backing material and covered with a translucent vinyl mortar. This allows the colours to extend right through to the backing, providing a longer wear life.

Audio for slide 14 (mp3)

Audio for slide 14 (mp3)

Roll widths Lay flat vinyl is designed to be laid with the minimum number of seams, so the choice of width is determined by the floor dimensions. Products imported from America are supplied in imperial widths - typically 6 feet (1.83 m) and 12 feet (3.66 m). If the products are made in Australia or Europe, they're supplied in metric sizes - generally 2 m, 3 m and 4 m.

Audio for slide 15 (mp3)

Audio for slide 15 (mp3)

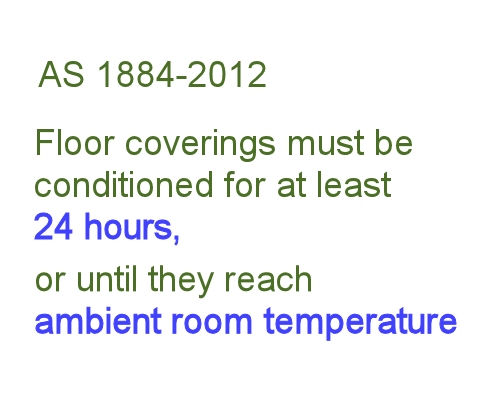

Conditioning. Before you begin an installation, you need to let the floor covering condition to the surrounding temperature and humidity in the room. This process is also called acclimatisation.

Audio for slide 16 (mp3)

Audio for slide 16 (mp3)

AS 1884-2012 says that floor coverings should be conditioned for at least 24 hours, or until the product has achieved an 'ambient room temperature' range of between 15° and 28° C. For more information on the conditioning process, including the procedures you should follow in buildings with air conditioners or heated floors, go to the lesson 'Conditioning' in the unit: Preparing floor coverings.

Audio for slide 18 (mp3)

Audio for slide 18 (mp3)

Adhesives are used to stick two surfaces together so they can't separate easily. There is a huge range of adhesive products designed for resilient floor coverings. However many of them are not suitable for lay flat vinyl because they can react with the backing and cause discolouration or damage. These products include polyurethane, contact and epoxy resin. We'll talk more about them in the unit: Commercial vinyl.

Audio for slide 19 (mp3)

Audio for slide 19 (mp3)

The two main types of products used to stick down lay flat vinyl are acrylic adhesive and double-sided tape. The methods used to install them are described in Section 4: Laying techniques.

Audio for slide 21 (mp3)

Audio for slide 21 (mp3)

Do you know why 'a good tradesman never blames his tools'? It's because he always uses the right tool for the job, and only ever uses tools that are in good condition. If a particular tool is malfunctioning or getting worn or going blunt - don't keep using it! If you can't fix the problem on the spot, put it to one side and either fix it later or replace it.

Audio for slide 22 (mp3)

Audio for slide 22 (mp3)

Remember that for every tool to perform properly and not let you down when it's needed, it has to be treated properly and kept in good working order. Set out below are the main hand tools used to install lay flat flooring.

Audio for slide 25 (mp3)

Audio for slide 25 (mp3)

There's a lot to think about when you carry out an on-site installation. Sometimes you can get so preoccupied with the specifics of the job that you forget about other important issues.

Audio for slide 26 (mp3)

Audio for slide 26 (mp3)

These include the arrangements that must be made in advance, the documentation you need to take, and the inspections you should carry out before you start the job. In this section, we'll talk about these general issues that apply to working on-site and preparing for the installation.

Audio for slide 28 (mp3)

Audio for slide 28 (mp3)

Depending on the size of the project you're working on, your client might be the owner of the property, or on larger installations, the builder or site manager. Whatever their role is in the overall project, they need to have the confidence that you'll do a high quality job and will act professionally at all times.

Audio for slide 29 (mp3)

Audio for slide 29 (mp3)

It's a very responsible position to be in when the client puts their trust in your abilities. If you repay that trust with an installation that meets their expectations and satisfies the standards, everyone will be happy at the end of the job. They'll be happy because they'll get a finished floor that represents good value for their money. And you'll be happy because you'll get paid without any quibbles.

Audio for slide 30 (mp3)

Audio for slide 30 (mp3)

But in addition to these immediate pay-offs, you'll have left behind an installation that demonstrates your commitment to a quality job. And as every good installer knows - there is no stronger advertisement than a happy customer's personal recommendation!

Audio for slide 31 (mp3)

Audio for slide 31 (mp3)

Presenting a professional image Here are some hints on how to present a professional image to the client when you show up on-site to carry out the installation: arrive on time, or if you're running late, phone the client to apologise and tell them what time you expect to be there when you arrive, introduce yourself by name and be courteous look at the project together and show them a floor covering plan that includes details on seam directions answer any questions they might have about specific aspects of the job tell them how long you expect to be working on-site carry in tools and materials carefully to avoid damaging doors, walls or other items be flexible, and try to work in with the client to avoid disruptions or inconvenience.

Audio for slide 32 (mp3)

Audio for slide 32 (mp3)

Making arrangements with the client If you work for a company with a supervisor or manager who organises the installations, everything should be ready for you when you arrive on-site. But if you're self-employed or work in a very small team, you may have to talk to the client yourself about any advance arrangements or preparations they are responsible for.

Audio for slide 33 (mp3)

Audio for slide 33 (mp3)

These include: making sure the job site is accessible on the date you've agreed to do the installation making sure no other trade work will be going on that would hold up your progress keeping pets and children out of the way and having as few other people on-site as possible.

Audio for slide 34 (mp3)

Audio for slide 34 (mp3)

There are some advance arrangements that you need to be particularly careful about, because they're the sorts of things you could each think the other party is going to organise. These include: who will move the furniture, appliances and any other items that are in the way who is responsible for disconnecting appliances, especially when an electrician or plumber is required who will remove and dispose of existing floor coverings and other fixtures.

Audio for slide 36 (mp3)

Audio for slide 36 (mp3)

It sometimes seems that there are lots of rules and regulations when it comes to safety on-site. But the basic formula for staying healthy and avoiding injures is really quite simple: use safe work practices at all times look for hazards before you start any new job and take actions to control them keep the workplace tidy, maintain a professional attitude and don't take shortcuts.

Audio for slide 37 (mp3)

Audio for slide 37 (mp3)

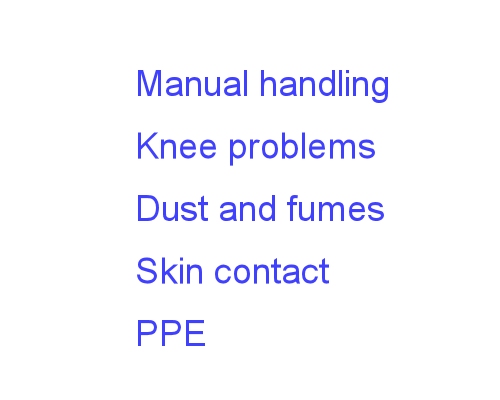

Many of the specific safety issues that you need to be aware of when you're laying a resilient floor are covered in other units in this Flooring Technology resource. Here they are in summary, together with the units they are discussed in: Manual handling - including how to lift and carry heavy rolls of flooring - see: Safety at work Knee problems - including injuries and chronic conditions caused by working on your knees - see: Safety at work Dust and fumes - including dust from subfloor preparations and fumes from primers and adhesives - see: Subfloor coatings and toppings Skin contact with hazardous substances - including cement-based products and solvents - see: Subfloor coatings and toppings Personal protective equipment - including eye protection, ear protection and other items of PPE needed on-site - see: Safety at work.

Audio for slide 38 (mp3)

Audio for slide 38 (mp3)

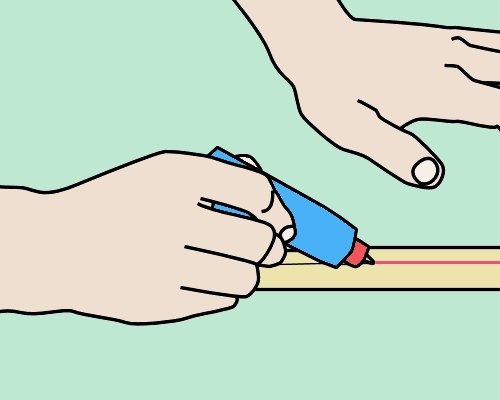

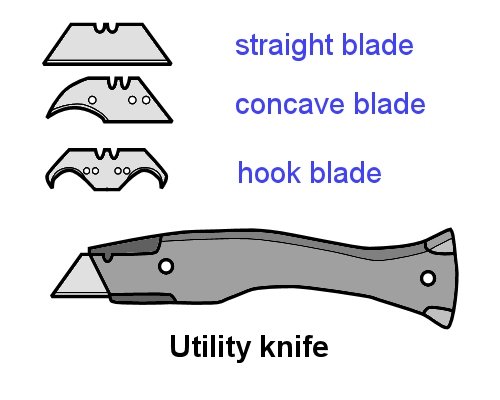

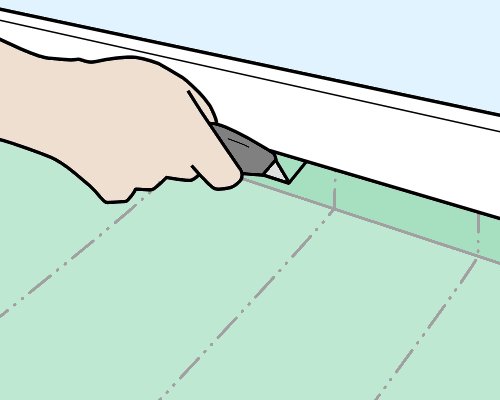

But there is one issue we haven't discussed yet that particularly applies to resilient floor layers - knife safety. The most common type of knife you'll use when laying a resilient floor is a utility knife. Below are the general safety procedures for using a utility knife to cut resilient floor products.

Audio for slide 39 (mp3)

Audio for slide 39 (mp3)

Utility knife safety procedures Use the right blade for the job. There are different blades for different uses, including straight, concave and hook blades. Always use the blade for the task it's designed for.

Audio for slide 40 (mp3)

Audio for slide 40 (mp3)

Keep the blade sharp. Change the blade whenever it starts to get blunt. If you need to force it through a cut or it begins to tear the material instead of cutting cleanly, it's time to replace the blade.

Audio for slide 41 (mp3)

Audio for slide 41 (mp3)

Pull the knife towards you. A pulling motion is stronger and can be controlled more easily than a pushing force, especially when you're cutting on a flat surface.

Audio for slide 42 (mp3)

Audio for slide 42 (mp3)

Keep your free hand clear. If you need to hold the material or a straight edge with your free hand, make sure it is not in the direct line of the cut.

Audio for slide 43 (mp3)

Audio for slide 43 (mp3)

Use a straight edge with sufficient thickness. If you need to use a straight edge, make sure it is thick enough to guide the blade without letting it ride up over the edge.

Audio for slide 44 (mp3)

Audio for slide 44 (mp3)

Use several passes on thick material. Cut progressively deeper with each pass, rather than trying to push the knife as deep as possible in a single cut.

Audio for slide 45 (mp3)

Audio for slide 45 (mp3)

Don't over-reach while you're cutting. Try not to reach further forward than your shoulders, and don't cut past your hip. If you stay within this area while you're cutting, you'll always have maximum control.

Audio for slide 46 (mp3)

Audio for slide 46 (mp3)

Don't bend the blade sideways. Blades are strong when the force is in the direction of the cut, but brittle if they're twisted at an angle. They are also totally unsuitable for use as a lever, and will snap easily if bent sideways.

Audio for slide 47 (mp3)

Audio for slide 47 (mp3)

Keep the knife in a scabbard or pouch. When you've finished using the knife, make sure you put it away safely. This helps to protect the blade and avoid injuries.

Audio for slide 49 (mp3)

Audio for slide 49 (mp3)

In the unit Planning and costing we talked about the sorts of documents you need to take with you when you go out to the site on installation day. The main document is the floor covering plan, which sets out the details relating to how the flooring will be installed.

Audio for slide 50 (mp3)

Audio for slide 50 (mp3)

You should always show the client the floor covering plan before you start a new project. This gives them the opportunity to identify any issues that they may not be happy with, or weren't expecting, before it's too late to make any changes. Some companies require the client to formally approve the plan by signing a copy.

Audio for slide 51 (mp3)

Audio for slide 51 (mp3)

Job sheet It's normal practice for the installer to be given a job sheet by the contracting company. A lot of the information is the same as in the floor covering plan, but there are also details relating to the specific products used and arrangements that have been made with the client.

Audio for slide 52 (mp3)

Audio for slide 52 (mp3)

The job sheet should include: jobsite address and contact details of the person in charge brand names and descriptions of the floor coverings to be laid details of other products to be used, including underlay, adhesive and trims seam placement and other installation details subfloor preparation required furniture and appliances to be moved unusual site conditions or potential problems.

Audio for slide 53 (mp3)

Audio for slide 53 (mp3)

Warranties and maintenance advice Most flooring installation companies provide their clients with a written warranty as part of the contract documentation. The warranty sets out the conditions under which the company will come back and fix problems that have occurred due to poor quality workmanship or faulty materials.

Audio for slide 54 (mp3)

Audio for slide 54 (mp3)

Hand in hand with the warranty conditions is the maintenance advice. This includes instructions on how to protect the floor immediately after installation, as well as general care and cleaning advice. It often comes in the form of a brochure produced by the flooring manufacturer.

Audio for slide 55 (mp3)

Audio for slide 55 (mp3)

It's important that you make sure the client understands the warranty conditions and maintenance advice. This not only helps them to do the right thing and enjoy the long-lasting performance of their floor, it also helps you to avoid a call back at some time in the future from a disgruntled customer!

Audio for slide 56 (mp3)

Audio for slide 56 (mp3)

The reason these two documents go together is because the warranty needs to be clear about who is 'liable' - or legally responsible - for particular types of problems. For example, it is the client's responsibility to follow the manufacturer's advice on how to maintain the floor and keep it in good condition. If they don't follow the advice and the floor suffers some sort of damage as a result, they can't expect the warranty to cover their expenses.

Audio for slide 58 (mp3)

Audio for slide 58 (mp3)

There's a variety of subfloors you're likely to encounter when installing resilient floor coverings. We discussed the main subfloor types and typical preparations in the following two units: Inspecting and testing subfloors Subfloor coatings and toppings. So in this lesson we'll summarise these issues by putting them into a set of questions that you should ask yourself before laying the floor covering.

Audio for slide 59 (mp3)

Audio for slide 59 (mp3)

Remember, as the flooring installer it's your responsibility to decide whether the subfloor is suitable and has been adequately prepared. If you're worried that the substrate isn't suitable, or that there is an underlying problem that might cause trouble later on, don't ignore it. Check with your supervisor or manager before going ahead. Everyone will be thankful in the long run, even if it means that there'll be a delay while the problem is fixed.

Audio for slide 60 (mp3)

Audio for slide 60 (mp3)

Questions to ask yourself General issues Is the substrate smooth and flat? AS 1884-2012 states that the planeness tolerance is 4 mm over a 2 metre length, and the smoothness tolerance is 1 mm over a 150 mm length.

Audio for slide 61 (mp3)

Audio for slide 61 (mp3)

Is the surface free from dirt, oil, adhesive residues and all other contaminants? Certain substances can interfere with the strength of the adhesive bond, and in some cases also discolour the vinyl surface.

Audio for slide 62 (mp3)

Audio for slide 62 (mp3)

Concrete subfloors Are the relative humidity (RH) and alkalinity (pH) levels within the allowable limits? There are strict limits set for RH and pH, both in the Australian Standards and in the flooring manufacturers' own installation instructions. The only time you should over-ride these specifications is when an approved moisture barrier is being installed.

Audio for slide 63 (mp3)

Audio for slide 63 (mp3)

Is the substrate sound and free from loose, powdery or scaly material? The concrete or underlayment surface must be sound and sufficiently porous to allow the adhesive to bond properly. If it's not in good condition, the affected layer will need to be removed and replaced with a new underlayment.

Audio for slide 64 (mp3)

Audio for slide 64 (mp3)

Are there expansion joints in the floor? Expansion joints need to be in good condition and free from dirt or obstructions. You'll need to keep them clear and finish them off with approved cover strips. Don't get mixed up with relief cuts that have been put into the concrete to stop it from cracking during the curing process. These will be a 5 mm wide saw cut, and can be filled with a suitable compound.

Audio for slide 65 (mp3)

Audio for slide 65 (mp3)

Have heating elements been installed in the floor? Flooring manufacturers provide recommended limits for the temperature of the subfloor. Make sure the heating elements will not exceed this temperature, and follow the specific instructions relating to substrate preparation for heated floors.

Audio for slide 66 (mp3)

Audio for slide 66 (mp3)

Wooden subfloors Is the existing floor properly supported and well secured? Any structural problems or loose boards should be fixed before the installation begins, especially squeaky floorboards or springiness in the floor surface.

Audio for slide 67 (mp3)

Audio for slide 67 (mp3)

Are there gaps between boards, protruding nail heads or other surface defects? Gaps, ridges, cupped boards, protruding nails, and other defects will 'telegraph' through to the surface of the floor covering. In general, structural floors made from plywood and strip flooring need to have a hard underlay placed on top to provide a flat smooth surface.

Audio for slide 68 (mp3)

Audio for slide 68 (mp3)

Is the subfloor ventilation adequate and in compliance with the relevant standards? Check that the air vents provide sufficient ventilation and that the subfloor cavity meets the minimum requirements for clearance between the floor and the ground.

Audio for slide 69 (mp3)

Audio for slide 69 (mp3)

Has the moisture content (MC) been checked and is it within the allowable limits? The moisture content of structural members and floor boards or sheets must all be within the allowable MC range. There must also be no evidence of plumbing or stormwater leaks that might have a long-term effect on the MC.

Audio for slide 70 (mp3)

Audio for slide 70 (mp3)

Old resilient floor coverings Some flooring installers lay new vinyl on top of old resilient coverings if they're well bonded to the subfloor. However, AS 1884 does not allow this practice because of the risks involved. It's also likely that you'll void the warranty on any new materials laid if you leave an existing covering underneath.

Audio for slide 71 (mp3)

Audio for slide 71 (mp3)

One of the main reasons for not putting new coverings on top of old is that you can never be sure the bond will stay sound. Sometimes it's the old adhesive that breaks down and causes a separation with the subfloor. At other times it can be the new adhesive that doesn't bond well to the old floor covering, often because of old polish or other ingrained contaminants on the surface.

Audio for slide 72 (mp3)

Audio for slide 72 (mp3)

There are also potential problems with different shrinkage rates between the two coverings, which may result in blistering, cracking or other surface defects. You can also end up with indentation problems in the new covering, because the old flooring has too much cushioning to provide adequate support or has existing grooves in the surface.

Audio for slide 75 (mp3)

Audio for slide 75 (mp3)

There are some standard installation methods that can be used with all sheet flooring products. These include the techniques used to mark and scribe material, cut seams and reliefs, match patterns and use templates.

Audio for slide 76 (mp3)

Audio for slide 76 (mp3)

Once you know these methods, you can apply the same principles to fitting cushioned vinyl, commercial vinyl, linoleum and any other sheet materials. So in this section, we'll discuss these general techniques for fitting, marking, scribing and cutting.

Audio for slide 78 (mp3)

Audio for slide 78 (mp3)

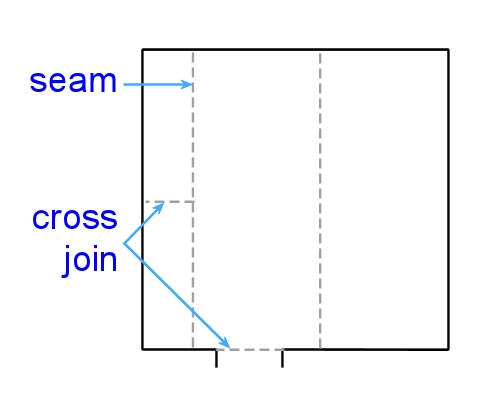

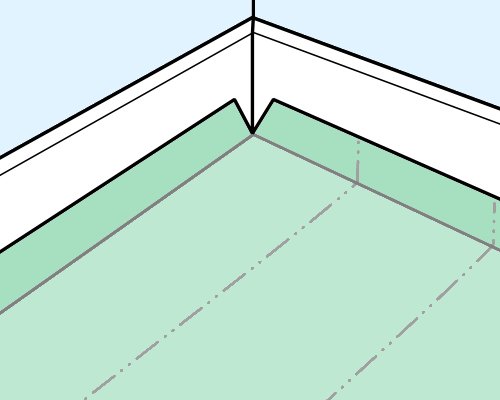

Seams occur in sheet flooring wherever two lengths join side by side. Cross joins occur where two ends meet - that is, where one roll finishes and the next one begins.

Audio for slide 79 (mp3)

Audio for slide 79 (mp3)

It is possible to overlap two sheets where they join and simply cut through both at the same time to form a seam. This is called double cutting. But it can result in an overly tight seam, which might 'peak' where the sheets butt together. It's also possible that the pattern may not match exactly.

Audio for slide 80 (mp3)

Audio for slide 80 (mp3)

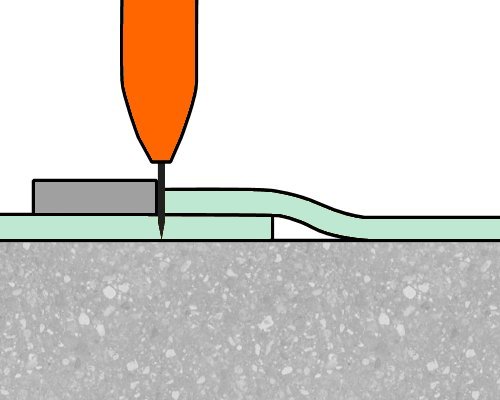

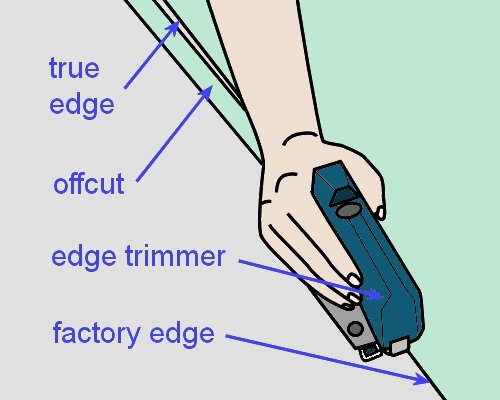

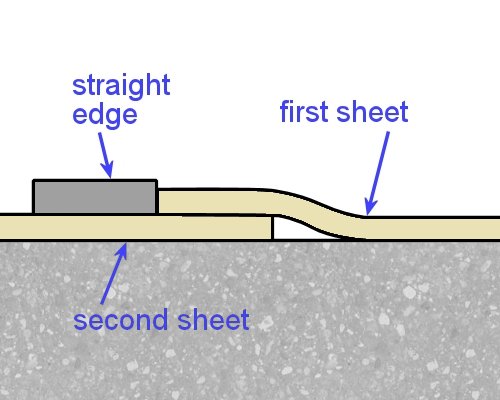

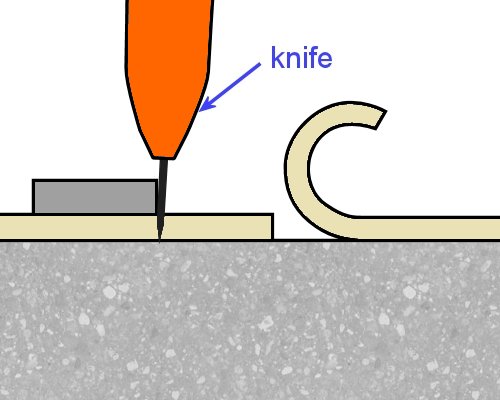

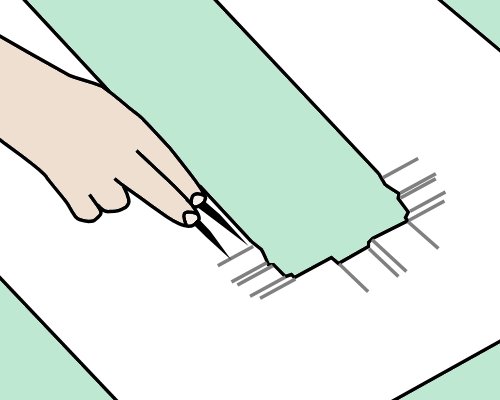

An alternative technique is to trim the factory edge off the first piece to remove any damage and produce a clean 'true' edge. You can either do this with an edge trimmer or a straightedge and knife. Then trace cut the second piece using the following procedure.

Audio for slide 81 (mp3)

Audio for slide 81 (mp3)

Trace cutting Cut a true edge along the line of the seam in the first sheet. Put the second sheet under the true edge of the first sheet and line up the pattern exactly. Push the straightedge up against the seam edge of the first sheet.

Audio for slide 82 (mp3)

Audio for slide 82 (mp3)

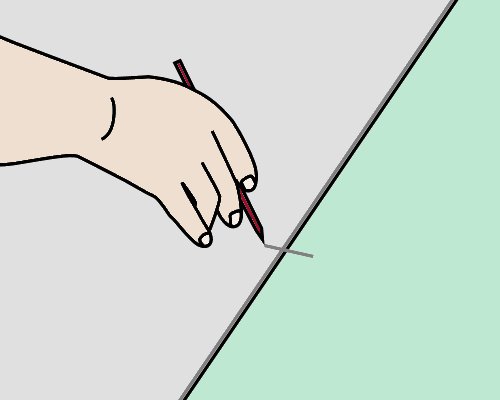

Hold the straightedge in position and fold back the first sheet. Cut the second sheet along the line of the straightedge, holding the knife as vertical as possible.

Audio for slide 83 (mp3)

Audio for slide 83 (mp3)

Batch lots Floor coverings are manufactured in batch lots, also called dye lots. Each roll of material has a batch number on the packaging to indicate which batch of colour dyes was used in that particular manufacturing run. It will also have a roll number.

Audio for slide 84 (mp3)

Audio for slide 84 (mp3)

Where possible, you should try to use flooring with the same batch number and sequential roll numbers when they are being placed side by side. This will help to provide the best match of colours and avoid any inconsistency in shade or intensity.

Audio for slide 85 (mp3)

Audio for slide 85 (mp3)

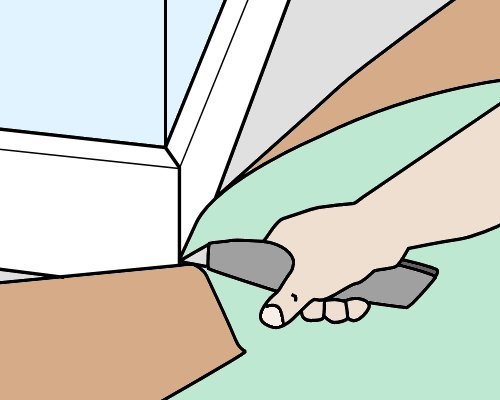

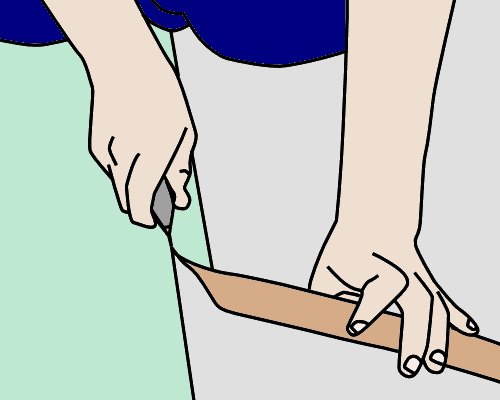

Using a utility knife The most common tool used for cutting is the utility knife. Because it's relatively thin, lay flat vinyl can be cut in a single pass with a straight, concave or hook blade. You can use the straight blade for general cutting. The concave blade is better for more precise cutting, such as around door frames. The hook blade has a flat heel, which stops the cutting edge from coming into contact with the surface underneath. This allows you to cut on a concrete floor or on top of another resilient sheet.

Audio for slide 86 (mp3)

Audio for slide 86 (mp3)

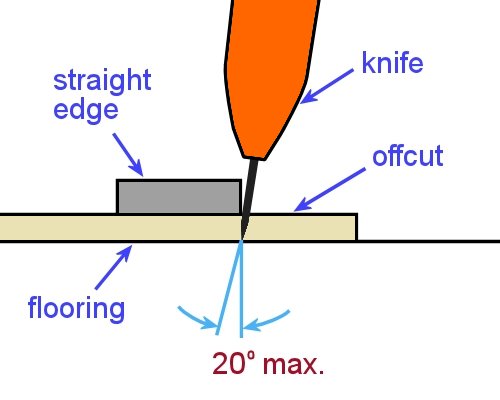

Most people tend to undercut the material slightly when the offcut is on the outside of their cutting hand. This is not a bad thing, because it gives you a sharp edge that butts cleanly against the next sheet or the wall.

But be careful that you don't undercut too much. If the undercut is more than about 20 degrees from the vertical, the edge might become too weak and break or fold over when it's butted up.

But be careful that you don't undercut too much. If the undercut is more than about 20 degrees from the vertical, the edge might become too weak and break or fold over when it's butted up.

Audio for slide 88 (mp3)

Audio for slide 88 (mp3)

The idea of freehand cutting is to put a slightly oversized piece of material in place on the floor and then cut and fit it in position. The procedure is as follows.

Audio for slide 89 (mp3)

Audio for slide 89 (mp3)

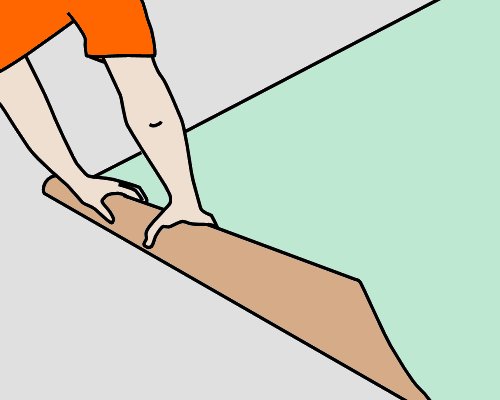

Pre-cut the piece outside the room in an area where you can lay it out full sized. Leave about 50 to 100 mm over-length at each end for re-trimming. Carry the piece into the room and lay it in place on the floor. If the piece is large, roll it up or 'tube' it first, with the face on the inside.

Audio for slide 90 (mp3)

Audio for slide 90 (mp3)

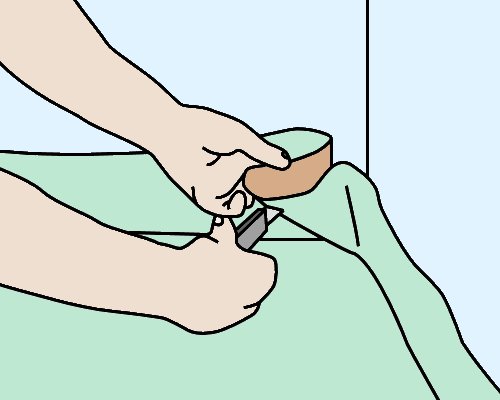

Make relief cuts at the junction between the floor and walls, so that the material lays flat without tearing. Trim the edges with a knife or wall trimmer so they fit tightly to the walls.

Audio for slide 91 (mp3)

Audio for slide 91 (mp3)

Relief cuts There are four basic relief cuts. They are designed to allow the material to be pushed down flat on the floor at the junctions with walls and other objects.

Audio for slide 92 (mp3)

Audio for slide 92 (mp3)

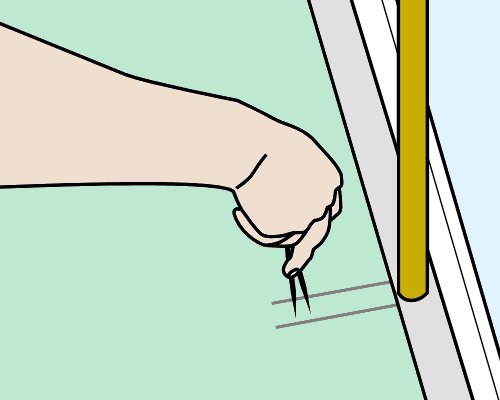

Curved or irregular shaped wall Put a vertical cut in the material where it flashes up against the wall. Keep the side of the knife against the wall to guide the cut and to avoid marking the wall. Make sure the cut isn't too deep, so it doesn't show in the finished job.

Audio for slide 93 (mp3)

Audio for slide 93 (mp3)

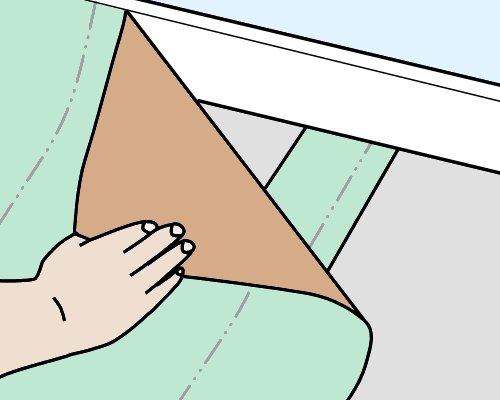

Inside corner Cut diagonally across the corner of the material from both sides. Push the material into the inside corner to check whether the cut is deep enough. Be careful not to cut too deep - it's best to cut in steps and check the fit after each cut.

Audio for slide 94 (mp3)

Audio for slide 94 (mp3)

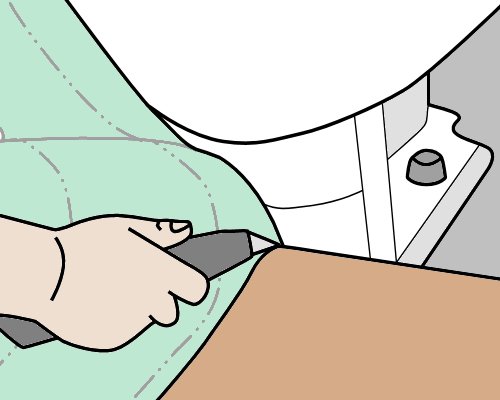

Outside corner Hold the material in position at the outside corner. Cut downwards towards the floor, following the line of the corner. Trim the material at the floor and wall juncture to avoid tearing it as you push it down flat.

Audio for slide 95 (mp3)

Audio for slide 95 (mp3)

Three sides of an object Flash the material up around the front of the object and push it in around the junction of the floor and object. Slit the material almost to the floor. Use a small crosscut at the bottom of the slit to stop the cut from tearing into the material. Work the material down to the floor, cutting it flat to the floor wherever there are buckles or pressure points.

Audio for slide 96 (mp3)

Audio for slide 96 (mp3)

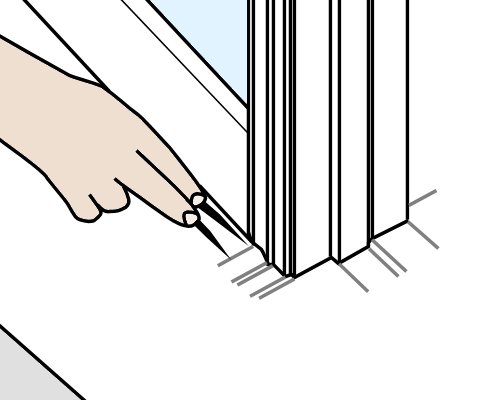

Other tricks Door jambs and architraves Where possible, undercut the door jambs and architraves to the thickness of the flooring material so it will fit underneath. Use a jamb saw or multi tool to cut the timber. If the jambs and architraves can't be undercut, fit the material by putting in relief cuts as you push it down.

Audio for slide 97 (mp3)

Audio for slide 97 (mp3)

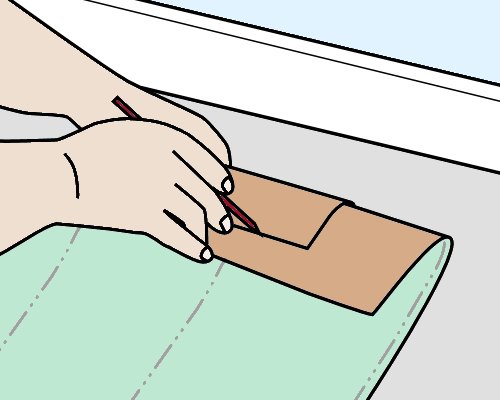

Strip measuring This method of measuring is useful when the wall is straight but hard to reach with the knife. Flash the material up the wall and then pull it back. Put a piece of scrap material with a squared end under the material and push it hard against the wall. Pull both pieces back together and mark the underside of the material at the end of the scrap piece. Do this several times along the wall.

Audio for slide 98 (mp3)

Audio for slide 98 (mp3)

Remove the scrap and fold the piece back so you can draw a continuous line along the marks with a straightedge. Don't forget to make an allowance for the curve of the material - the scrap piece will have slid back slightly due to the curvature. Cut the material from the underside, being careful not to cut right through to the material underneath.

Audio for slide 100 (mp3)

Audio for slide 100 (mp3)

Direct scribing is used in areas where you need to install more than one piece of material. The most common technique is the three-wall scribe. The procedure is described below. Once you've read through this process, go to the web link shown in the learning activity to see a video clip of a floor layer demonstrating the technique.

Audio for slide 101 (mp3)

Audio for slide 101 (mp3)

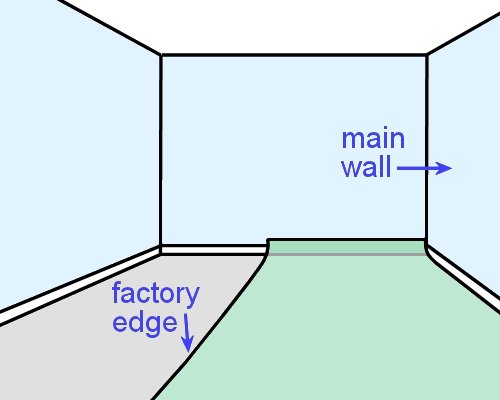

Place the material in the room with both ends flashed up the wall and the long side as close to the 'main wall' as possible. The main wall is the one that runs the full length of the piece. It is always scribed first.

Audio for slide 102 (mp3)

Audio for slide 102 (mp3)

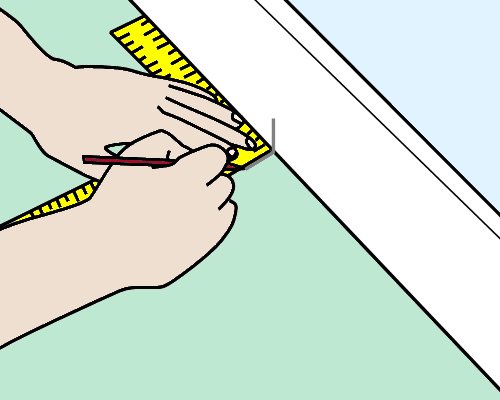

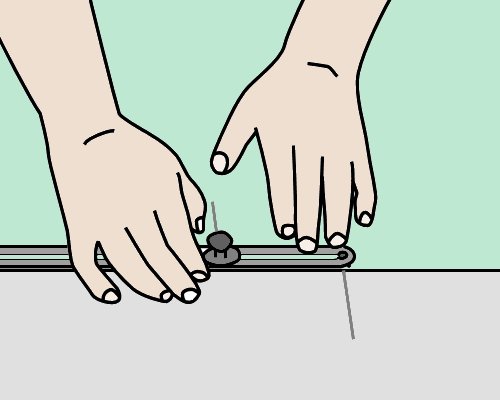

Mark a cross line on the wall (or skirting) and the material for alignment purposes. These two lines will be matched up later once you've cut the piece. Pull the sheet back from the wall by about 100 mm, making sure it stays parallel to the wall. Check that the distance is the same at both ends.

Audio for slide 103 (mp3)

Audio for slide 103 (mp3)

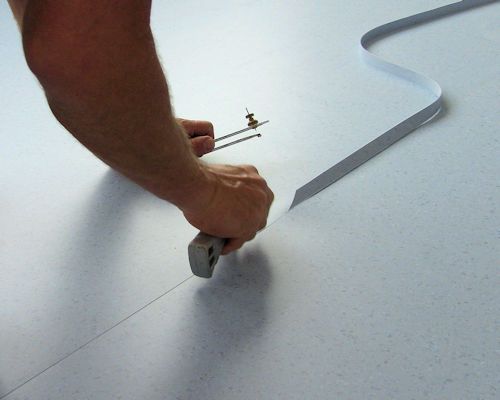

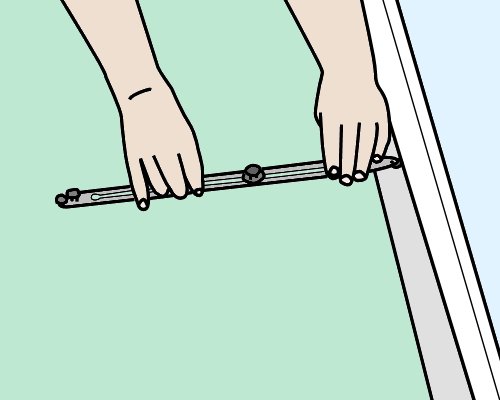

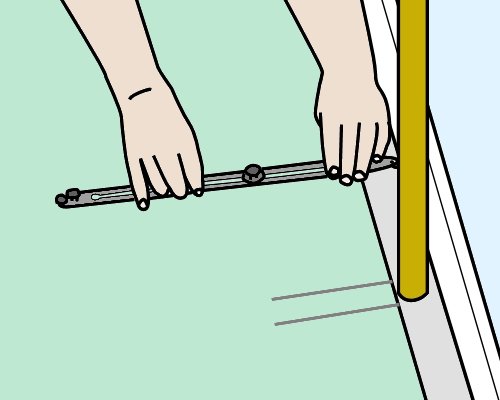

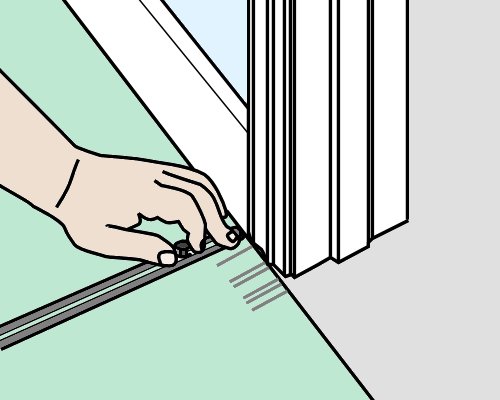

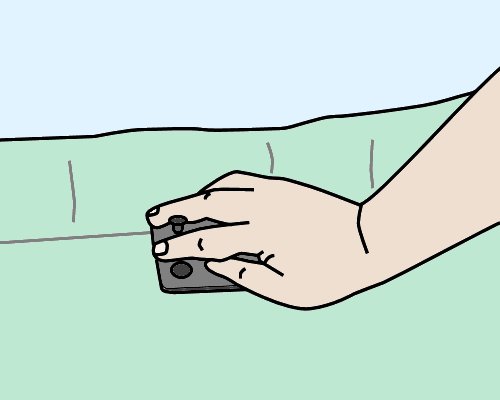

Use dividers or a bar scriber to scribe the outline of the main wall onto the material. Set the scriber so it marks about 10 to 20 mm in from the edge of the sheet. Make sure you hold the scriber at right angles to the sheet while you're marking the line. Cut along the scribed line with a knife. Then move the piece back into place against the main wall and line up the pencil marks.

Audio for slide 104 (mp3)

Audio for slide 104 (mp3)

Trim the 'factory edge' off the other side to produce a clean straight edge. Draw a guide line on the subfloor with your pencil held firmly while it follows the edge of the sheet. Then put a cross line from the edge of the material to the subfloor. Pull the piece away from the end wall until it lies flat on the floor. Make sure the edge stays aligned with the long line you've drawn on the subfloor.

Audio for slide 105 (mp3)

Audio for slide 105 (mp3)

Set the bar scriber to the difference between the two cross lines (one on the subfloor, the other on the material). Scribe the end of the piece to the end wall. Cut along the scribed line. Carry out the same scribing and cutting procedure at the other end.

Audio for slide 106 (mp3)

Audio for slide 106 (mp3)

Pipes To scribe a wall and pipe at the same time, first mark the position of the pipe with two offset lines running square from the wall. Use the same scribe setting as you've used for the wall and mark the front of the pipe between the offset lines.

Audio for slide 107 (mp3)

Audio for slide 107 (mp3)

Scribe a circle with the dividers, touching both offset lines and the scribe mark. Cut a seam into the circle, and cut out the scribe line for the wall and a circle for the pipe.

Audio for slide 108 (mp3)

Audio for slide 108 (mp3)

Door trims Door jambs and architraves can be scribed in the same way. Draw a separate line for each change in direction, at right angles to the wall. Then use the bar scriber to mark the profile of the architrave.

Audio for slide 109 (mp3)

Audio for slide 109 (mp3)

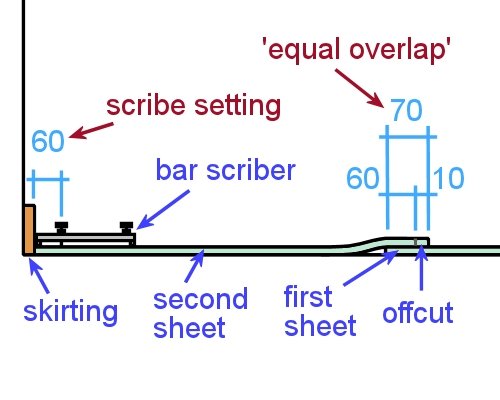

Pattern matching To pattern-match a second piece of material beside the first piece, use the three-wall scribe technique. Trim off the factory edge of the first piece where the seam will be. Then bring the second piece into the room. Put it in place with its inside edge overlapping the first piece and the other edge against the main wall (running lengthwise). Make sure the overlap is equal for the entire length of the seam.

Audio for slide 110 (mp3)

Audio for slide 110 (mp3)

To find the scribe setting for the main wall, subtract the width of the offcut that you'll trim off the inside factory edge. For example, if the 'equal overlap' at the seam is 70 mm and the offcut is 10 mm, the scribe setting should be 60 mm. This means that you will still have a 10 mm overlap at the seam when you pull the material back to the wall once it has been cut.

Audio for slide 112 (mp3)

Audio for slide 112 (mp3)

Pattern scribing is used when a shape is complicated or the area is very small. It involves scribing the outline onto pattern paper and cutting out the template. This allows the outline to be transferred onto the flooring material so it can be cut to shape in an open area before it's placed in position on the floor. The process is as follows.

Audio for slide 113 (mp3)

Audio for slide 113 (mp3)

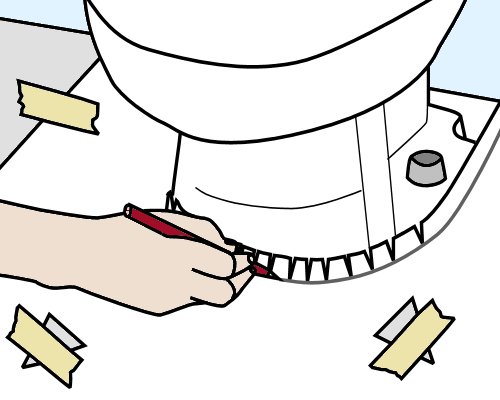

Lay the paper in position and cut it roughly to shape, to within about 10 mm of all objects and protrusions. Around a toilet pedestal you can make relief cuts in the paper as you push it down to the floor, and then run a pencil line around the bottom of the cuts, where the pedestal meets the floor. Secure the paper firmly in position using weights, drawing pins or tape. If you use sticky tape, you should cut small triangular flaps into the template so the tape sticks to the floor through the openings.

Audio for slide 114 (mp3)

Audio for slide 114 (mp3)

Use a rule and sharp pencil to trace around the object, with the rule pressed firmly against the outline of the object. Alternatively, you can use dividers or a bar scriber to get the same result. At architraves and other offsets, extend lines out at right angles for each change in direction.

Audio for slide 115 (mp3)

Audio for slide 115 (mp3)

When all objects in the room have been extended onto the template, take it outside and lay it on top of the floor covering. Fasten the template to the material with tape so it can't move. Extend all of the lines from the template onto the material and cut the material to shape. Put the material in position and check the fitting. Then spread the adhesive and stick the material down.

Audio for slide 118 (mp3)

Audio for slide 118 (mp3)

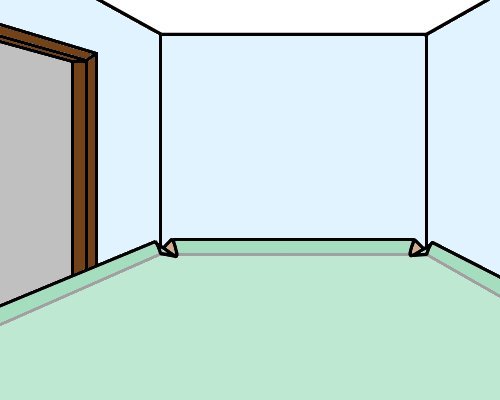

There are two basic methods for installing lay flat vinyl - loose lay and full spread. When the floor covering is laid without any adhesive underneath, it's called loose lay. When it is stuck down with adhesive, it's called full spread. An alternative to full spread is 'perimeter stick' - where the adhesive is only spread around the perimeter of the floor area. However, this is not recommended by some manufacturers because it can cause the material to buckle.

Audio for slide 119 (mp3)

Audio for slide 119 (mp3)

In this section we'll discuss the loose lay and full spread installation methods. We'll also cover the techniques used to cold weld seams and joins. And we'll wrap up with the final inspection and clean-up of the finished job.

Audio for slide 121 (mp3)

Audio for slide 121 (mp3)

Because there is no adhesive used under a loose laid floor, most manufacturers say that cushioned vinyl should only be loose laid in areas up to 25 m2. However, some of the heavier types of lay flat vinyl can be loose laid on floors up to 40 m2. Note that these areas include all connecting rooms.

Audio for slide 122 (mp3)

Audio for slide 122 (mp3)

Loose lay is not suitable for floors that will take heavy traffic, or where there is furniture that may be pushed around. This includes furniture or appliances on roller casters.

Audio for slide 123 (mp3)

Audio for slide 123 (mp3)

Joins should be cold welded with a chemical seam sealer. To help secure the seam you can also use double-sided tape underneath. However, this doesn't mean that you should put tape around the perimeter of the floor. Although some manufacturers allow this 'perimeter stick' method of securing the edges, there is a risk that the material may buckle if there is any movement in the covering.

Audio for slide 124 (mp3)

Audio for slide 124 (mp3)

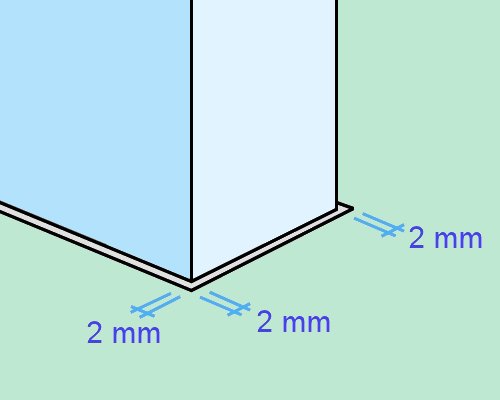

Lay flat vinyl is very stable and won't shrink or curl over time if it's laid properly. Nonetheless, in prolonged hot weather it can grow slightly. For this reason, you should leave a gap of about 2 mm around the perimeter of the material so that it can't buckle up against skirting, cupboards or door frames.

Audio for slide 125 (mp3)

Audio for slide 125 (mp3)

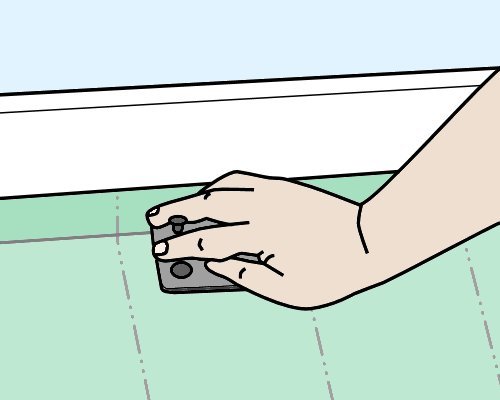

To install loose laid vinyl: Lay out the material and allow it to acclimatise to the temperature and humidity of the room. Some installers like to reverse-roll the vinyl to relieve the stresses before laying it out on the floor.

Audio for slide 126 (mp3)

Audio for slide 126 (mp3)

Cut off all excess material, leaving about 100 mm flashed up the walls for the final trim. V cut all corners to allow it to sit flat on the floor. If you haven't already reverse-rolled the material, let it relax for about one hour before starting the final trimming.

Audio for slide 127 (mp3)

Audio for slide 127 (mp3)

Brush the surface with a soft broom to remove any trapped air. Make sure it is sitting flat on the substrate. Use a knife or wall trimmer to cut the sheet to size. Cut and fit the sheet lengthwise first. Leave the ends until last, to give the vinyl more time to acclimatise.

Audio for slide 128 (mp3)

Audio for slide 128 (mp3)

If more than one sheet is required, fit the larger sheet first. Overlap the second sheet by about 20 mm, or according to the pattern match required. Try to avoid placing seams in thoroughfares. To cut a seam between two sheets, place a straight edge over the overlapping sheets where the cut will go, and hold it firmly in place while you cut as vertically as possible through both sheets. Note that on thicker vinyls you'll need more than one pass to cut right through both sheets - never force the knife through the material.

Audio for slide 131 (mp3)

Audio for slide 131 (mp3)

Full spread is also called 'full stick', meaning the material is stuck down with adhesive that's spread right across the floor. Manufacturers generally specify acrylic adhesive for lay flat vinyl flooring. The installation procedure is as follows:

Audio for slide 132 (mp3)

Audio for slide 132 (mp3)

Cut and fit the vinyl in the same way as for loose lay. Once the vinyl has been fitted, fold it back and apply adhesive to the subfloor.

Audio for slide 133 (mp3)

Audio for slide 133 (mp3)

Wait for the adhesive to 'tack up' and then press the vinyl into position. Broom out any air bubbles. Roll the floor thoroughly with a roller, making sure that all trapped air has been removed.

Audio for slide 135 (mp3)

Audio for slide 135 (mp3)

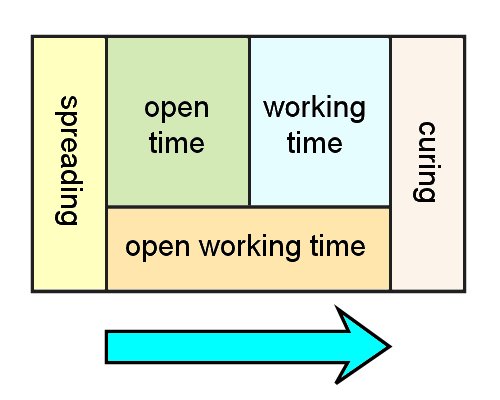

Adhesive 'open time' Once an adhesive has been spread on the floor, you need to wait until the open time has elapsed before placing the floor covering in position. This is also called the tack up time, because the ridges in the adhesive start to 'skin over'. But don't wait until it becomes touch dry - for the adhesive to grab it needs to be able to stick to your fingers and pull back when you lift your hand off. Installers describe this stickiness as 'having legs'.

Audio for slide 136 (mp3)

Audio for slide 136 (mp3)

Having said that, you should also make sure that the flooring isn't placed into the adhesive too soon. Wet adhesive gives off gasses, and if it isn't allowed sufficient time to tack up, the gasses can get trapped under the floor covering and cause bubbles under the surface.

Audio for slide 137 (mp3)

Audio for slide 137 (mp3)

Adhesive 'working time' When the adhesive is ready for the flooring to be placed on top, the working time begins. This is the time you have available to lay the material and complete all cutting and fitting. If you place flooring into the adhesive after the working time has passed, the flooring won't bond properly.

Audio for slide 138 (mp3)

Audio for slide 138 (mp3)

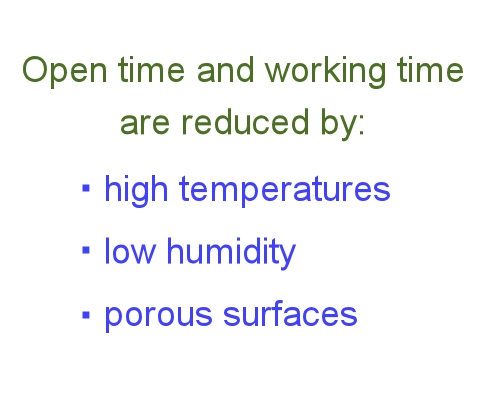

Note that the open time and working time of an adhesive will vary depending on the temperature, humidity and porosity of the surface. High temperatures, low humidity and porous surfaces will all reduce these times.

Audio for slide 139 (mp3)

Audio for slide 139 (mp3)

For very porous surfaces, such as wood-based underlays, manufacturers generally specify that a primer be applied first with a brush. This helps to avoid the problem of late placement, where the adhesive has already set and will no longer bond to the flooring covering.

Audio for slide 140 (mp3)

Audio for slide 140 (mp3)

Manufacturers often combine the open time and working time and specify a working open time for their adhesives. The duration begins when the adhesive is spread and continues through to the time when you should no longer place the flooring into the adhesive. It particularly applies to adhesives that skin over almost immediately.

Audio for slide 141 (mp3)

Audio for slide 141 (mp3)

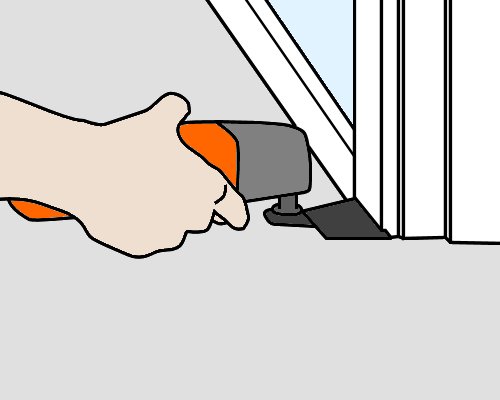

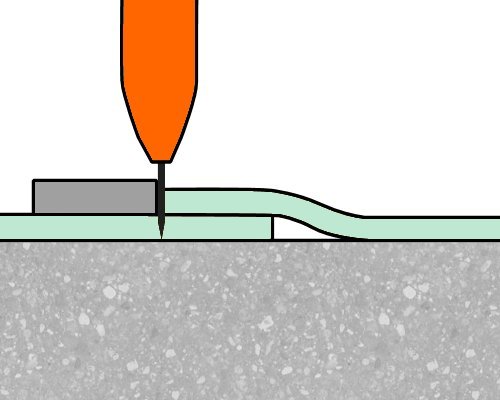

Notched trowels Most adhesives are designed to be spread on the floor with a notched trowel. These trowels have square or V shaped notches cut into one or both sides of the blade. Their purpose is to control the amount of adhesive that's spread on the substrate.

Audio for slide 142 (mp3)

Audio for slide 142 (mp3)

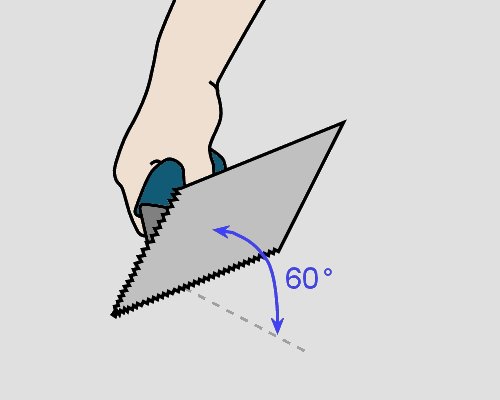

Trowels are designed to be held at a 60° angle to the floor while you're spreading. If the angle is too flat, the ridges in the adhesive will be too low, so there won't be enough to ooze out and fill the spaces when the floor covering is pushed down on top.

Audio for slide 143 (mp3)

Audio for slide 143 (mp3)

Manufacturers sometimes specify different trowel notchings for particular flooring and adhesive products. It's important to follow these specifications, because if you don't, you'll end up applying either too much or too little adhesive. Applying too much adhesive can result in the ridges showing through the floor covering surface, or 'bleeding' at the joints. Applying too little will mean that there is less adhesive available for a firm bond, as well as a reduced working time for placement.

Audio for slide 144 (mp3)

Audio for slide 144 (mp3)

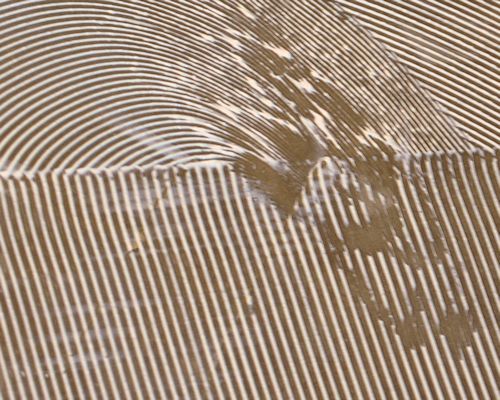

This photo shows what can happen if the adhesive isn't spread evenly. Large gaps are sometimes called 'windows of opportunity' - because they create the opportunity for a very bad outcome when the material doesn't stick properly!

Audio for slide 145 (mp3)

Audio for slide 145 (mp3)

Over time, the notches in the trowel will gradually wear down and reduce the depths, especially when you're working on cement-based substrates. So whenever the trowel starts to show signs of wear, it should be replaced. Alternatively, you can reshape the notches using a triangular file. For more details on the sorts of problems that can occur with adhesives and a troubleshooting table on problems and their causes, see the lesson 'Problems with adhesives' in the unit: Commercial vinyl.

Audio for slide 146 (mp3)

Audio for slide 146 (mp3)

Rollers Once the floor covering has been placed in position and fitted, it needs to be pushed firmly into the adhesive. You should do this with a heavy floor roller, running lengthwise and then across the floor.

Audio for slide 147 (mp3)

Audio for slide 147 (mp3)

In areas that can't be reached with a floor roller, use a hand roller. Be sure to roll the edges and seams properly, because these are the areas where adhesive failures tend to start.

Audio for slide 149 (mp3)

Audio for slide 149 (mp3)

Cold welding is also called chemical welding, because it uses a solvent to fuse the two sides of a seam together. The process is applied widely to carpets and PVC products in all sorts of applications - but in resilient floors it's generally only used with cushioned vinyl that isn't suitable for heat welding.

Audio for slide 150 (mp3)

Audio for slide 150 (mp3)

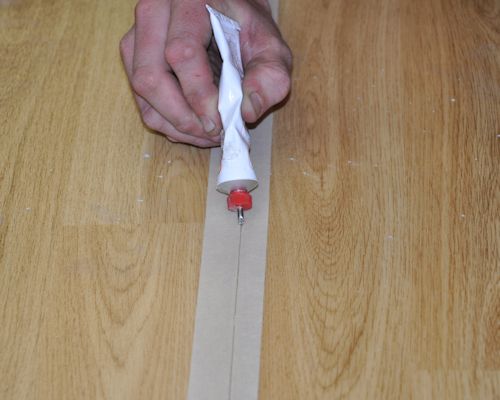

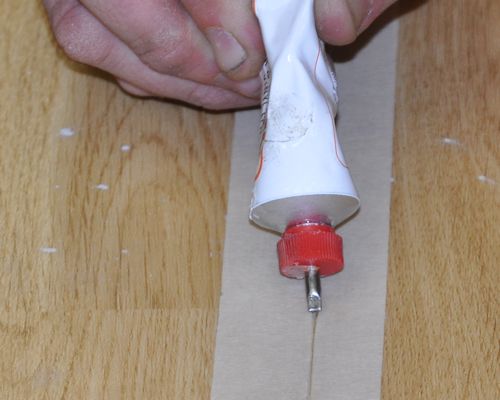

You should always wait until the following day after installation before cold welding the seams. This allows the adhesive to set and gives the moisture from the adhesive time to evaporate. Some manufacturers recommend a full 24 hours before cold welding. Set out below is the general procedure for seam sealing with a PVC cold welding liquid. Typically, this product comes in a tube and is applied through a steel needle attached to the tube's nozzle. However, there are variations on this technique, so you should always follow the specific instructions provided by the manufacturer.

Audio for slide 151 (mp3)

Audio for slide 151 (mp3)

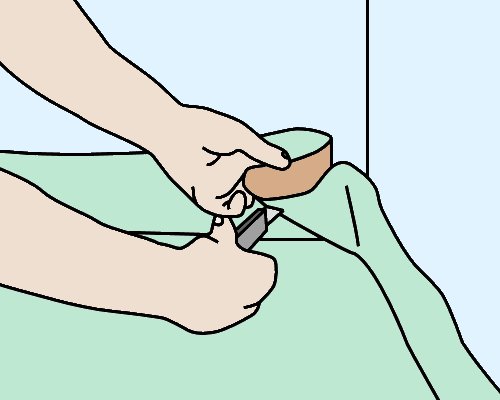

General procedure Place masking tape over the seam and press it down firmly. Cut through the masking tape over the join between the two sheets using a straight knife.

Audio for slide 152 (mp3)

Audio for slide 152 (mp3)

Press the needle of the tube firmly into the seam and pull the tube along the join. Control the flow of liquid so that a 5 mm wide glue line appears on top of the masking tape. Wait about 10 minutes for the glue to bond and then pull the masking tape off.

Audio for slide 154 (mp3)

Audio for slide 154 (mp3)

Once you've completed the installation you should carefully check the finished floor to make sure everything looks right. If you do find any problems, fix them straight away - don't wait for complaints or call backs from the client.

Audio for slide 155 (mp3)

Audio for slide 155 (mp3)

In particular, look for: loose edges or seams adhesive on the surface trapped air bubbles or buckles in the flooring. Doing a final inspection of your work is also an excellent way of evaluating your installation techniques and learning where you can improve your skills.

Audio for slide 156 (mp3)

Audio for slide 156 (mp3)

Protecting the new floor On projects where it's your job to move heavy appliances back into position, use plywood panels or other board products as protection underneath the appliance. Slide the first board under the object as you lift it off the floor one side at a time. Then put another board beside the first one and push the object over the boards. Don't roll or drag the object directly across the new flooring material.

Audio for slide 157 (mp3)

Audio for slide 157 (mp3)

If you're leaving the client to move the appliances themselves, give them instructions on how to do it properly so they don't put a tear or buckle in the floor covering. Even objects on wheels or casters need to be pushed across wood panels, because if the adhesive isn't fully cured they'll leave grooves in the floor surface. Commercial floors should be protected from rolling loads for at least 72 hours after the installation is finished.

Audio for slide 158 (mp3)

Audio for slide 158 (mp3)

Housekeeping Clients appreciate tidy tradespeople - especially if you're working in their home. Take all your rubbish and materials with you, except for left-over pieces of floor covering that might be useful to the client for future repairs.

Audio for slide 159 (mp3)

Audio for slide 159 (mp3)

Be particularly careful with hazardous products that need to be disposed of in an approved way. Don't put materials or rubbish in doorways or other access ways, because they'll probably get knocked over and end up being a trip hazard. Keep everything well stacked and out of everyone's way.