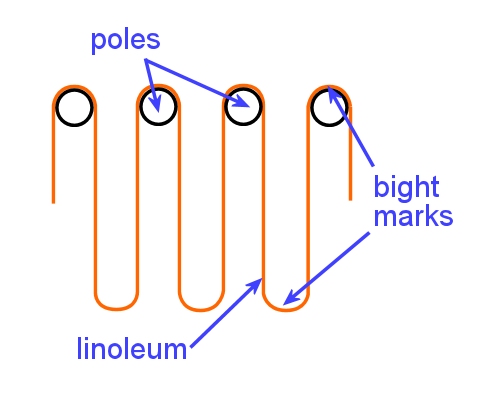

Bight marks and end curls

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

The bight marks at the top are cut out at the factory and the discarded material is recycled.

However, the marks at the bottom of each loop are left in the sheet.

In the finished roll they often appear as a slight ridge across the sheet, about 150 mm wide.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

But with 3.2 mm material, or if the temperature is cool, you may need to either cut out the bight mark or use the following technique:

- As you feed the sheet into the wet adhesive and reach the bight mark, lean gently on the mark and rock it in and out of the adhesive, making sure there is a complete transfer of adhesive onto the hessian backing.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

- When the loop of material being fed into the adhesive clears the area of the bight mark, immediately roll it with a 68 kilogram roller and remove any bubbles or trapped air.

- Continue to roll the bight mark every 15 minutes until it has fully bonded to the subfloor.

An alternative method is to use contact adhesive on the subfloor where the bight mark falls. For more information on this process, see the Forbo Floorcoverings Installation Guide'

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

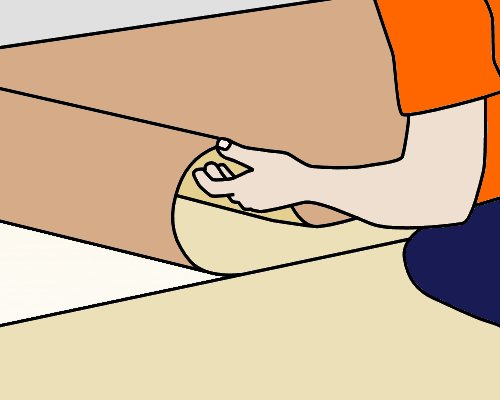

Removing end curl

The end of the linoleum sheet also needs to be laid carefully, to make sure that the hessian backing beds well into the adhesive.

If you fold the corner back diagonally and use a 'bouncing' action as you place it into the adhesive, it will help to relieve the tension in the end of the length.

Then roll the sheet thoroughly with a floor roller.

Learning activity

Audio 6 (mp3 |6|KB)Go to the video clip called 'Forbo marmoleum sheet installation video':

Forbo Marmoleum sheet installation video

Watch the clip and then answer the following questions:

- When should you roll out the material after it has been laid into the adhesive?

- What would happen to the sheet if you didn't massage the end curl before you laid it into position?

- What does the presenter suggest you do with the adhesive to help the 'stove bar' (bight mark) bond properly to the subfloor?

Go to Border coving

Go to Border coving