Cutting and welding

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

Cutting seams

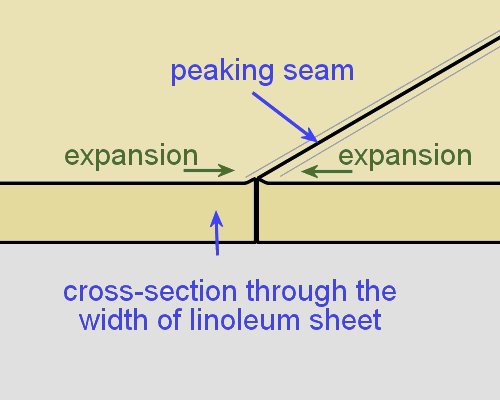

When linoleum is rolled out and placed into the adhesive, the hessian-backed material picks up moisture from the atmosphere and adhesive.

This causes a small amount of expansion across the width of the sheet, which stops when the adhesive starts to cure.

Even though the expansion is only tiny, it can cause the seam to peak if you don't make allowance for it.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

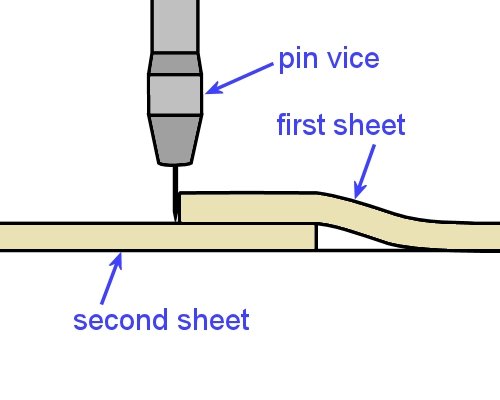

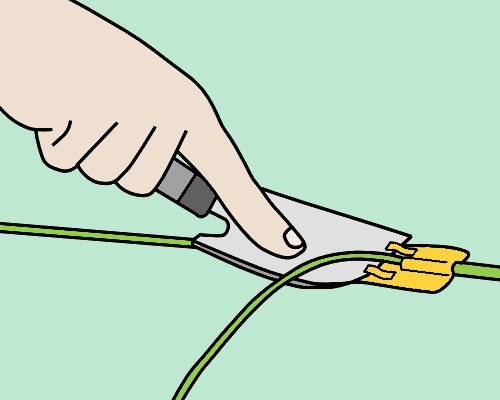

The allowance only needs to be about the thickness of the pin in a pin vice.

You can accommodate any expansion by using the following procedure:

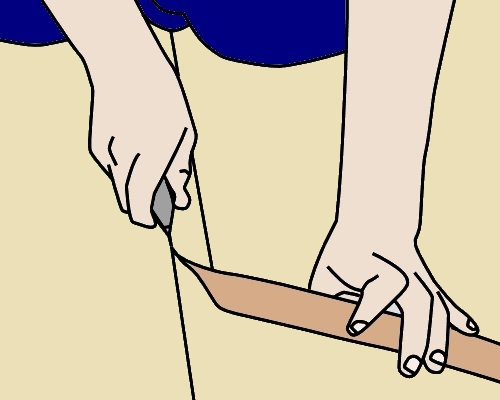

- Cut the true edge in the first sheet of linoleum as you would for commercial vinyl.

- Lap the second sheet under the first sheet, either matching up the pattern or leaving a 20 mm overlap.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

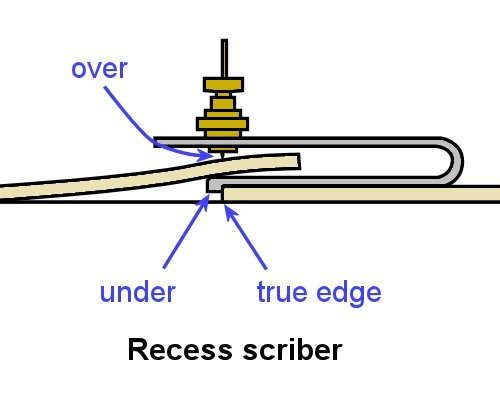

But remember to offset the scribe pin by the thickness of the pin to achieve the same result as described before.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

Fitting long lengths

If the sheet is long, it will tend to shrink slightly along the length, so you need to make allowance for the shrinkage when you cut the sheet.

One method of dealing with the shrinkage is to only scribe one end and stick down the sheet up to about the last 2 metres.

Then scribe the second end, spread the remaining adhesive and stick that end down.

Note that the whole sheet must be stuck down while the adhesive is still wet. If the first part starts to set before you lay down the last section, any overspread in adhesive might result in bubbles where the two parts meet.

Audio for slide 8 (mp3 |6|KB)

Audio for slide 8 (mp3 |6|KB)

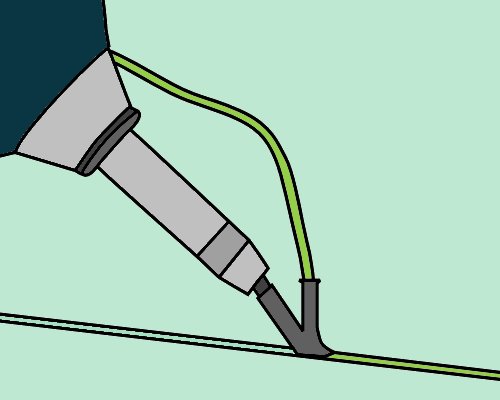

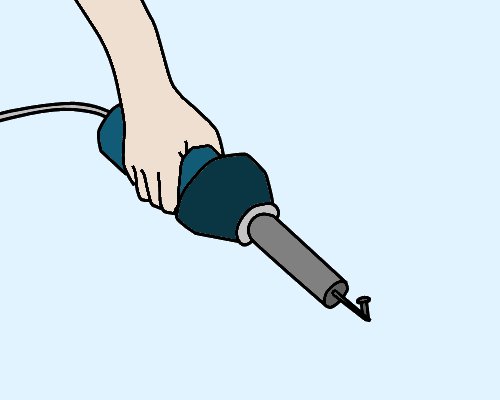

However, the welding cable is different, and linoleum is welded at a lower temperature and slower speed.

The chemical reaction that occurs in the welded joint is also different.

In vinyl, both the flooring material and welding cable melt and fuse together; but in linoleum, only the cable melts as it bonds to the routed seam.

Learning activity

Audio 10 (mp3 |6|KB)The link below will take you to a Forbo video on the correct use of adhesive when installing Marmoleum.

This video provides a good review on the difference between 'open time' and 'working time', which we discussed in the unit Commercial vinyl.

It also explains the differences in technique that apply to linoleum, compared to the practices used for commercial vinyl.

Watch the clip and then answer the following questions:

- What conditions will affect the 'open time' and 'working time' of an adhesive?

- What does 'fully wet' mean?

- What does 'semi-wet' mean?

- What does 'flashed off' mean?

- At what stage of the drying process should you lay the sheet into the adhesive?

- What is one of the most common causes of installation failure in Marmoleum?

Go to

Go to